Chapter 1: Definition and Core Concepts of PU Leather

PU leather, short for polyurethane synthetic leather, is a man-made material made with a polyurethane resin as its primary coating, applied to various substrates (usually fabrics) to mimic the look and feel of natural animal leather.

Core Ingredients:

Polyurethane (PU): This is a high-molecular-weight polymer with excellent abrasion resistance, flex resistance, flexibility, and plasticity. In PU leather, it primarily serves as the surface coating, responsible for the leather's texture, color, gloss, and much of its tactile feel. High-quality PU resin can create a highly realistic grain effect.

Backing Material: This is the base to which the PU coating is applied, typically a fabric. The most common backing materials are:

Knitted fabric: Flexibility and softness are common in clothing and shoe uppers.

Non-woven fabric: Low cost and easy to produce, often used in low-end products or packaging.

Woven fabric (such as polyester and cotton): High strength and dimensional stability, often used in luggage and furniture. Microfiber substrate: This high-end substrate is made of extremely fine fibers, with a structure more similar to the collagen fiber network of genuine leather. This creates microfiber PU leather, the highest-end variety of PU leather.

Working Principle: PU leather is produced by coating or laminating a liquid polyurethane slurry onto a base fabric. This is then heat-cured, embossed, and other processes to create a composite material with leather-like texture and properties.

Chapter 2: PU Leather Manufacturing Process

PU leather production is a complex process, primarily divided into the following steps:

Base Fabric Treatment: First, the selected fabric base fabric undergoes pretreatment, including cleaning, ironing, and impregnation, to ensure a smooth surface and facilitate bonding with the PU coating.

Polyurethane Slurry Preparation: Polyurethane particles are dissolved in a solvent such as DMF (dimethylformamide), and various additives (such as colorants, anti-wear agents, plasticizers, and coagulants) are added to form a uniform slurry.

Coating: The prepared PU slurry is evenly applied to the base fabric using equipment such as a scraper or roller. The thickness and uniformity of the coating directly determine the quality of the final product. Coagulation and Film Formation: The coated material enters a coagulation bath (usually a water bath). Water undergoes a displacement reaction with the DMF in the slurry, causing the PU resin to gradually precipitate and solidify, forming a thin film layer with a microporous structure. This microporous structure imparts a certain degree of breathability to the PU leather.

Washing and Drying: The material undergoes multiple water washes to thoroughly remove any residual DMF solvent, followed by drying.

Surface Treatment (Finishing): This is a critical step in giving the leather its "soul."

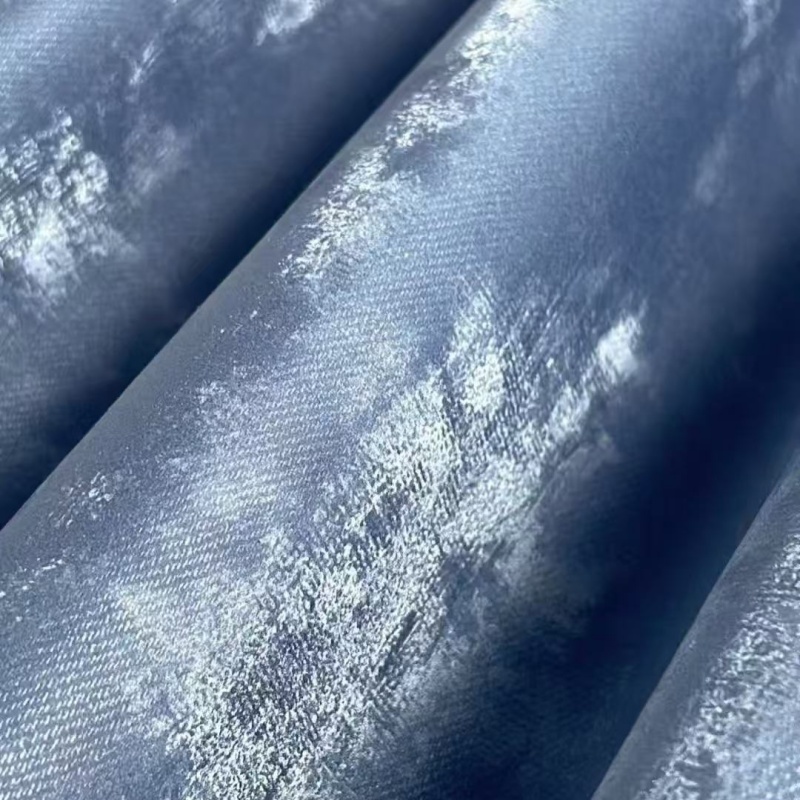

Embossing: Metal rollers imprinted with leather grain (such as lychee, tumbled, or nappa) are pressed against the surface under high temperature and pressure to create the desired texture.

Printing: More complex patterns and even patterns resembling those of exotic animal hides can be printed.

Finishing: A protective film is applied to the surface, such as a wear-resistant layer, a matte layer, or a feel agent (such as a smooth, waxy, or silicone-like finish) to enhance appearance and durability.

Coiling and Inspection: Finally, the finished product is rolled into a roll and, after quality inspection, shipped.

Chapter 3: Characteristics, Advantages, and Disadvantages of PU Leather

Advantages:

Low Cost: This is the most significant advantage of PU leather. Its raw material and production costs are far lower than those of animal leather, making the end product very affordable.

Uniform Appearance and High Utilization Rate: PU leather is an industrialized product, resulting in perfectly uniform color, texture, and thickness on each roll. It is free of the natural defects found in animal leather, such as scars, moth bites, and wrinkles, and virtually no waste is produced during cutting.

Easy Care: It offers excellent water and stain resistance, allowing common stains to be removed with a damp cloth, eliminating the need for specialized maintenance oils.

Various Colors and Design Freedom: Embossing and printing techniques can be used to mimic the grain of any animal leather (such as crocodile or ostrich), even creating colors and patterns not found in nature, offering designers unlimited creative freedom.

Lightweight: It is typically lighter than animal leather of the same surface area.

High Consistency: Mass production ensures consistent product quality, eliminating significant variations in feel and performance within the same batch.

Environmentally Friendly and Animal-Friendly: It does not directly use animal fur, which aligns with the principles of vegetarians and animal protection organizations. Modern technology also tends to use more environmentally friendly water-based PU resins to reduce solvent pollution.

Chapter 4: PU Leather vs. Other Materials

1. PU Leather vs. PVC Leather

PVC leather (commonly known as "Xipi"): Coated with polyvinyl chloride. It is an earlier generation of artificial leather.

Comparison: PVC leather is generally harder, less flexible, has very poor breathability (almost no micropores), feels more plasticky, and is prone to brittle cracking at low temperatures. PVC production is also less environmentally friendly. Therefore, PU leather outperforms PVC leather in almost all performance aspects and is currently the mainstream artificial leather choice.

2. PU Leather vs. Microfiber Leather

Microfiber leather: Made from a microfiber non-woven fabric base impregnated with polyurethane. It is currently the highest-end artificial leather.

Comparison: Microfiber leather's base structure closely resembles genuine leather, resulting in strength, durability, breathability, and feel far superior to ordinary PU leather, very close to top-grade genuine leather, and even surpassing it in some physical properties (more wear and tear resistance). Of course, its cost is also much higher than that of ordinary PU leather. You can think of it as a "luxury upgrade of PU leather."

Chapter 5: The Wide Range of PU Leather Applications

Due to its balanced performance and cost, PU leather has an extremely wide range of applications.

Fashion Apparel: Jackets, pants, skirts, belts, etc. It is the most commonly used leather alternative material for fast fashion brands.

Shoes and Bags: Decorative parts for sneakers, casual shoes, and boots; a large number of handbags, wallets, and school bags.

Furniture Upholstery: Sofas, dining chairs, bedside covers, car seats, steering wheel covers, interior panels, etc. Due to its wide variety of patterns and easy cleaning, it is widely used in the home and automotive sectors.

Electronic Products: Phone cases, tablet cases, headphone cases, laptop cases, etc.

Other: Stationery covers, jewelry boxes, gloves, various packaging, and decorative items.

Chapter 6: How to Choose and Care for PU Leather Products

Purchasing Tips:

Look: Check whether the grain is uniform and perfect. Genuine leather has natural irregularities in its grain. A cross-section of PU leather will reveal a distinct fabric layer. Touch: Feel the texture. Good PU leather should be soft and delicate, while poor quality can feel hard and plasticky. Also, feel the temperature. Genuine leather conducts heat faster and feels cool to the touch, while PU leather feels closer to room temperature.

Smell: Genuine leather has a distinct leathery odor, while PU leather often has a faint plastic or chemical odor.

Press: Pressing the surface with your fingers will cause natural, radial wrinkles to form, which recover slowly. PU leather, on the other hand, has stiff or subtle wrinkles that recover quickly.

Care:

Cleaning: Regularly wipe the surface with a soft, damp cloth to remove dust and stains. For stubborn stains, use a dedicated artificial leather cleaner; avoid harsh solvents.

Avoid: Avoid prolonged exposure to sunlight or heat sources to prevent the coating from aging and cracking. Avoid contact with sharp objects.

Storage: Store in a cool, dry place, preferably wrapped in a dust bag. Avoid heavy pressure.

Repair: Severe damage to the surface coating is difficult to repair and usually requires patching or professional repair.

Chapter 7: Future Development Trends

Environmentalization: The development and use of water-based PU resins (solvent-free), bio-based PU (derived from plants), and recyclable recycled PU materials are key areas of focus.

High-Performance: Through technological advancements, PU leather's functional properties, such as breathability, hydrolysis resistance, stain resistance, and flame retardancy, will be further enhanced, broadening its applications in specialized fields such as outdoor and medical applications.

Bionic Intelligence: Developing biomimetic leather materials with intelligent features such as "adaptive" temperature regulation and color change.

High-End: Microfiber PU leather technology will continue to mature, steadily encroaching on the high-end market share of traditional genuine leather and providing a virtually authentic experience.

Conclusion

As a remarkable material innovation, PU leather has played a significant role in democratizing design, meeting mass consumer demand, and promoting animal protection. While not perfect, its balance of cost, design, and functionality has secured it an unshakable position in the modern material world. Understanding its properties can help us make smarter consumer choices: when we seek uniqueness, durability, and value, genuine leather may be the answer; and when we need fashion, ease of use, and affordability, PU leather is undoubtedly an excellent choice. With technological advancements, the future of PU leather is bound to be even more environmentally friendly and superior.

Post time: Sep-11-2025