Chapter 1: Glitter's Definition - The Science Behind the Brilliance

Glitter, commonly known as "glitter," "sequins," or "golden onions," is a small, highly reflective decorative flake made from a variety of materials. Its core purpose is to create a shimmering, dazzling, and colorful visual effect by reflecting light.

From a scientific and industrial perspective, a more precise definition of glitter is possible:

Glitter is a microscopic optical reflective element with a specific geometric shape, formed by precisely cutting a multi-layer composite material (typically consisting of a reflective layer, a color layer, and a protective layer).

This definition includes the following key elements:

Material Composition (Multi-layer Composite Material):

Substrate Layer: This is the carrier of the glitter and determines its basic physical properties (such as flexibility, temperature resistance, and weight). Early and inexpensive glitters used paper as the substrate, but plastic films (such as PET, PVC, and OPP), metal foils (such as aluminum foil), and even biodegradable materials (such as PLA) are now more common.

Reflective Layer: This is the source of the glitter's sparkling effect. It is typically achieved by vacuum-depositing aluminum onto the substrate. High-purity aluminum is evaporated under a vacuum and evenly deposited onto the substrate surface, forming a mirror-like reflective film with extremely high light reflectivity.

Color layer: The aluminum layer itself is silver. To achieve the color effect, a transparent or translucent colored coating (usually a resin paint or ink) is applied above or below the aluminum layer. If the color is above the aluminum layer, light must pass through the color layer and be reflected back, creating a deep color. If the color is below the aluminum layer (between the substrate and the aluminum layer), it produces a different metallic luster effect.

Protective layer: To protect the reflective layer and color layer from scratches, oxidation, and corrosion during daily use, the outermost layer is usually covered with a transparent protective film (such as a resin coating). This film also affects the glossiness of the Glitter (high gloss or matte).

Manufacturing process (precision cutting):

After the multi-layer composite material is formed, it is cut using a precision punch equipped with a specific die. These dies are engraved with the desired shape (such as hexagon, square, circle, star, etc.). The precision of the cutting directly determines the smoothness of the Glitter's edges and the aesthetics of the finished product.

Form and Function (Micro-Optical Reflective Element):

Each Glitter fragment is an independent optical unit. Its tiny size (ranging from tens of microns to several millimeters) and random orientation enable it to reflect light from countless angles when illuminated, creating a dynamic, non-fixed "shimmering" effect, fundamentally different from the one-way reflection of a mirror.

In short, Glitter is not a single substance, but a craft that combines materials science, optics, and precision manufacturing technologies.

Chapter 2: Glitter's Classification System - A Multiverse

Type 1: Glitter Mesh Lace Fabric

Glitter mesh lace fabric refers to a composite decorative fabric created by weaving sequins, metallic threads, or shimmering fibers (such as Lurex) onto a traditional mesh lace base, creating a dazzling, shimmering effect. It perfectly blends the perspective of the mesh structure, the delicate patterns of lace craftsmanship, and the visually stunning "Glitter" elements, making it a high-end, functional lace.

Its main advantages are as follows:

1. Strong Visual Expression: Its greatest strength lies in its opulent decorative qualities. The combination of shimmering elements and delicate lace creates a strong visual impact, creating a noble, dreamy, and eye-catching effect, making it an ideal material for creating a focal point.

2. Rich Texture and Layering: It combines the softness of lace, the lightness and transparency of mesh, and the luxurious shimmer of shimmer, resulting in a rich, layered feel, significantly enhancing the product's quality and artistic value. 3. Excellent Breathability: Inheriting the DNA of mesh fabrics, even though the fabric may appear slightly thicker due to the sequined inlays, its hollow structure still ensures good air circulation, making it relatively comfortable to wear.

4. Flexibility and Versatility: Its base, often containing spandex, offers excellent stretch and flexibility, adapting to the body's curves and facilitating its application in a variety of complex clothing and accessory designs. It is highly sought after in high-end fashion, bridal gowns, lingerie, and luxury home decor.

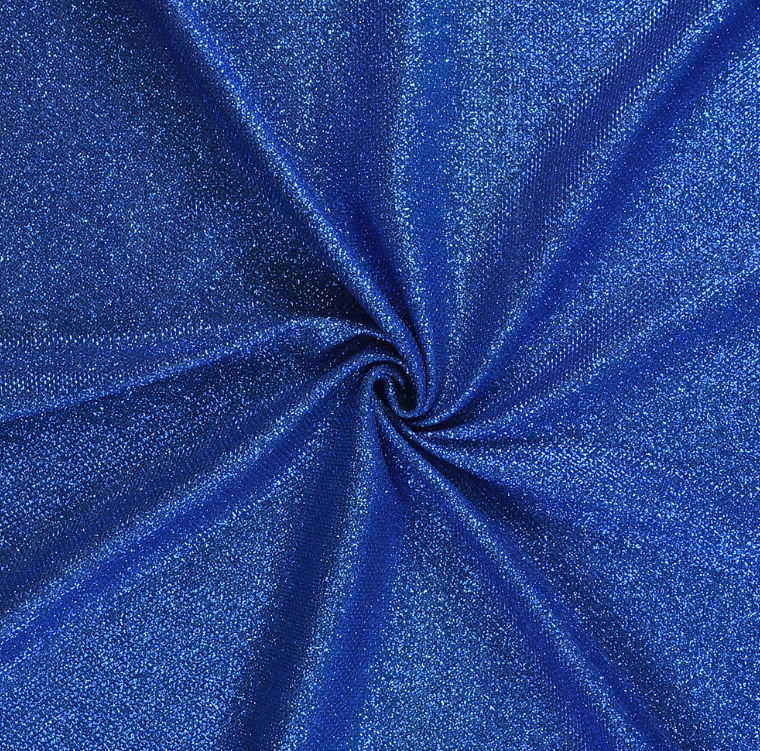

Type 2: Glitter Metallic Fabric

Glitter Metallic Fabric isn't woven from actual metal. Instead, it's a functional fabric that uses modern textile technology to incorporate shimmering elements into the fabric, giving it a strong metallic luster and dazzling visual effect. Its core principle is to simulate the texture and reflective properties of metal using various materials.

Key Advantages of Glitter Metallic Fabric

Strong Visual Impact and Fashionability: Its most prominent advantage is its ability to instantly capture light, creating a dazzling effect. Whether in luxurious gold and silver or avant-garde iridescent colors, it easily creates a sophisticated, technological, or futuristic atmosphere, making it a favorite for runway fashion, stage costumes, and high-end brand design.

Unique and Layered Texture: Unlike the monotonous texture of traditional fabrics, Glitter Metallic Fabric successfully simulates the cool luster of metal with the soft touch of fabric. This contradictory combination creates a rich sense of depth. The fabric's surface creates a dynamic flow of light and shadow as the lighting and viewing angle change, greatly enhancing the product's visual depth and artistic expression.

Improved physical properties: Blended with modern fibers, it overcomes the stiffness and heaviness of pure metal. High-quality shimmering metallic fabrics offer excellent flexibility and drape, making them easy to cut and sew. Furthermore, they are far more wear-resistant and corrosion-resistant than ordinary metal products, extending their service life.

Wide applications and vast design potential: From haute couture dresses and streetwear to luxury home decor (such as curtains and pillows), automotive interiors, and electronic product packaging, their applications are vast. Technological advances have also enabled the emergence of novel effects such as holographic and iridescent colors, offering designers endless creative possibilities.

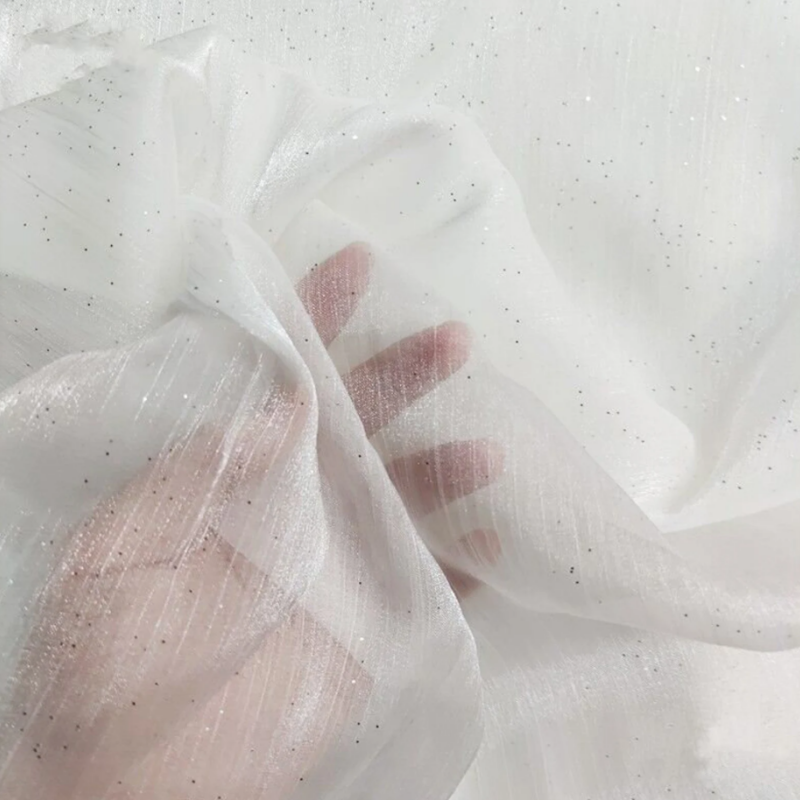

Type 3: Glitter Organza Fabric

Glitter organza is a synthetic fabric that combines a traditional organza base with shimmer, creating a crisp, transparent texture and a dazzling visual effect. Its core element lies in the combination of "organza" and "shimmer." Organza itself is a thin, plain weave fabric woven from high-twisted nylon or polyester yarn, resulting in a stable structure, lightweight texture, and a slight stiffness. The shimmer effect is primarily achieved by incorporating metallic threads, coated shimmer yarn (such as Lurex), or a pearlescent coating.

Main Advantages of Glitter Organza Fabric

1. Dreamy Visual Layering: Its greatest strength lies in its unique visual appeal. The brilliance of the shimmer combined with the translucent, hazy quality of the organza creates a dreamlike effect. Light penetrates the yarn and is reflected by the shimmering points, creating a rich and three-dimensional visual dimension far exceeding that of ordinary tulle.

2. Maintaining Shape While Appearing Light: Organza inherits its inherent stiffness and texture, easily supporting three-dimensional shapes like puffy skirts and exaggerated sleeves without becoming limp or clinging. Its exceptionally light weight ensures a weightless feel, perfectly balancing styling and lightness.

3. Enhanced Texture and Versatile Application: The addition of shimmering elements significantly elevates organza's luxurious and modern feel, elevating it from a common interlining to a highly expressive, leading fabric. It is widely used not only in wedding dresses, evening gowns, and stage costumes, but also in high-end window screens, fashion accessories, and other applications that require a dreamy atmosphere.

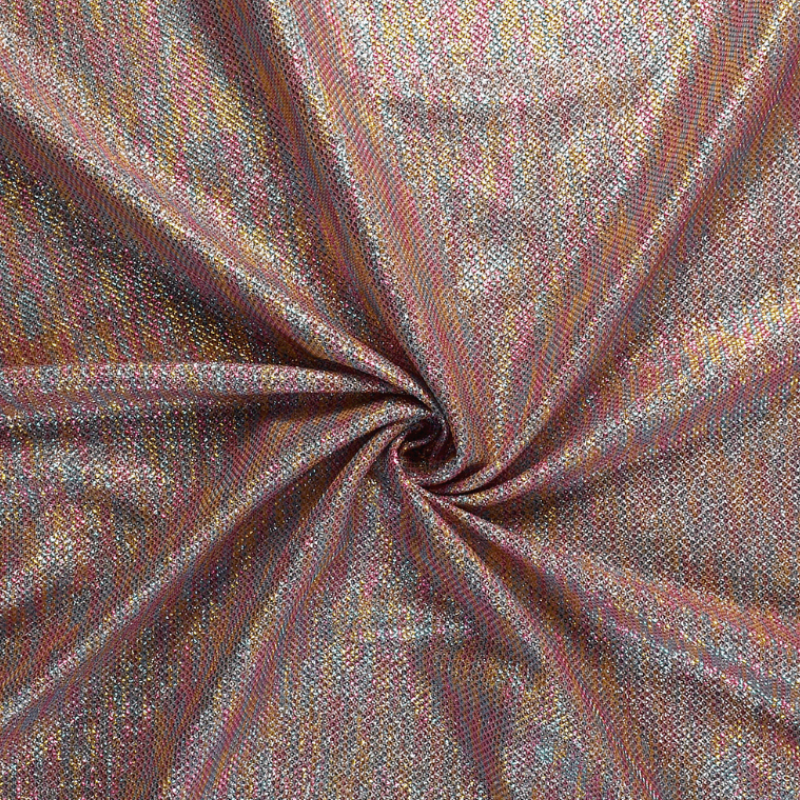

Type 4: Glitter Satin Fabric

Glitter satin fabric is a high-end fabric woven using a satin weave and combined with glitter fibers or finishing processes, resulting in a smooth satin texture and a shimmering sheen. Its core lies in the combination of a satin structure and shimmer elements. The satin weave utilizes long floating yarns (warp or weft) interlaced to maximize the coverage of the fabric surface with yarns running in the same direction, creating an exceptionally smooth and delicate feel. The shimmering effect comes from blended metallic yarns, coated polyester yarns (such as Lurex), or post-weaving gloss coatings and calendering.

Main Advantages of Glitter Satin Fabric

1. Luxurious Look and Feel: Its most notable advantage is its successful fusion of the premium texture of satin with the dazzling luster of metal. Its mirror-like surface feels smooth and velvety, while simultaneously shimmering with a subtle or exaggerated shimmer, instantly elevating the visual quality and luxurious feel of a product. It is commonly used in evening gowns, high-end fashion, and luxury homewares.

2. Dynamic Light and Shadow Effects: Compared to ordinary satin, this fabric boasts a more layered and dynamic sheen. As the wearer moves or the light angle changes, the fabric's surface creates a fluid play of light and shadow, creating a vivid and three-dimensional visual effect with a strong artistic appeal.

3. Excellent Drape and Comfort: Typically made from materials with excellent drape, such as silk, polyester, and acetate, this fabric allows garments to conform naturally and smoothly to the body's curves, creating a beautiful silhouette. Furthermore, its smooth surface reduces friction against the skin, providing a comfortable, next-to-skin feel.

Type 5: Glitter Sequins Fabric

Glitter sequin fabric is not a traditional "textile" fabric. Instead, it is a composite decorative material composed of numerous individual micro-sequins (sequins) attached to a mesh, gauze, or knitted base through sewing or weaving. Each sequin is typically made of aluminized plastic (such as PET), PVC, or metal, with a central hole for threading. Its core principle is to create an extremely dazzling visual effect through the collective reflection of countless tiny mirrors. It is a "functional" fabric with decorative properties as its primary purpose.

Main Advantages of Glitter Sequin Fabric

1. Extreme visual impact and dynamic beauty: This is its core advantage. Thousands of sequins create an unparalleled, dazzling reflection that is extremely eye-catching in any light. As the wearer moves, the sequins flip and ripple, creating a flowing, shimmering play of light and shadow. The dynamic effect far surpasses that of other glitter fabrics, creating a highly dramatic and expressive effect.

2. Create a three-dimensional silhouette and luxurious texture: Sequins inherently possess a certain hardness and weight, giving fabrics a more rigid form than ordinary fabrics and creating a more sculptural silhouette. Their dense and orderly arrangement creates a unique texture and tactile feel, creating an exceptionally luxurious, retro, and luxurious quality.

3. Strong thematic and artistic expression: Sequins offer an infinite variety of colors, shapes (round, square, scale, etc.), and arrangements, making them an ideal medium for expressing specific styles (such as disco, retro, and nautical). More than just a clothing material, they serve as a direct tool for artistic expression, making them ideal for stage costumes, fashion shows, and gala dresses, instantly capturing the attention of the audience.

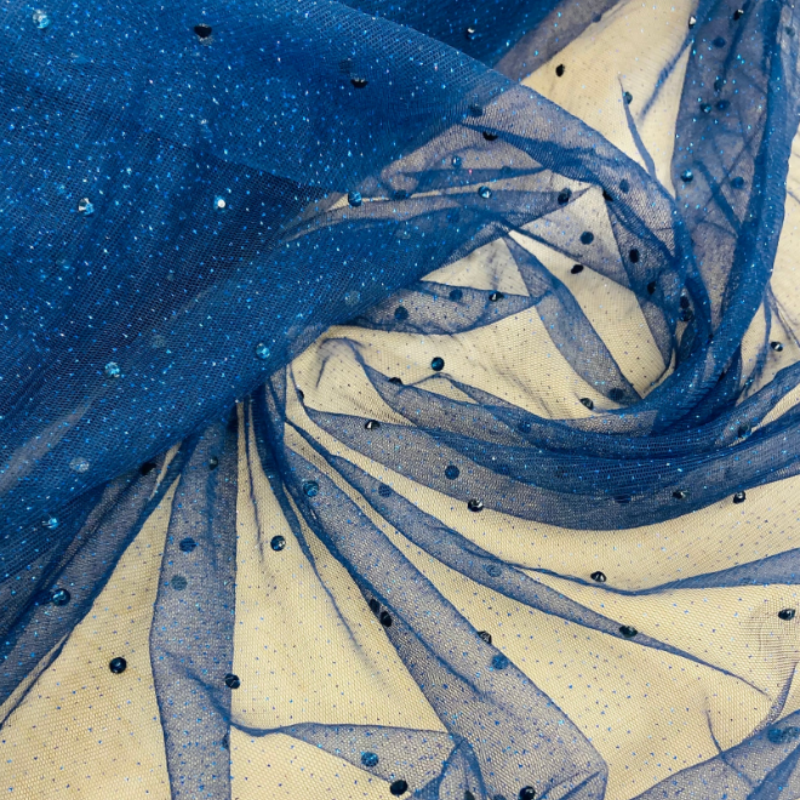

Type 6: Glitter Tulle Fabric

Definition of Glitter Tulle Fabric

Glitter tulle is a composite fabric that cleverly incorporates glitter elements onto the lightweight mesh base of classic tulle, creating a dreamy, translucent feel with twinkling sparkles. Traditional tulle is typically made from materials like nylon and polyester using a net weave method, resulting in a light, fluffy texture but lacking luster. The "glitter" effect is achieved by weaving in metallic threads and sequins, embedding glitter fibers, and applying a pearlescent coating. This process elevates the once-plain tulle into a more expressive and modern decorative material.

Main Benefits of Glitter Tulle Fabric

Creating a dreamy, hazy visual atmosphere: Its greatest strength lies in its unique visual magic. The brilliance of the glitter interweaves with the soft, hazy texture of the tulle, reminiscent of stars in the night sky, creating a romantic, dreamy, and layered visual effect. This shimmer is less direct than that of metallic fabrics, but rather softer, more diffused, and imbued with an airy quality.

Maintaining Ultimate Lightness and Dynamics: Despite the addition of shimmer, the fabric retains its exceptionally lightness. As it sways with the footsteps, the shimmering dots shimmer, lending the garment a dynamic and agile aesthetic without appearing heavy or rigid due to embellishment.

Enhancing Support and Versatility: Tulle inherently offers a certain degree of stiffness and support, allowing it to be created into three-dimensional forms, such as puffy bustles and dreamy sleeves. The addition of shimmer further elevates its opulence, transforming it from a backdrop to a centerpiece. It is widely used in wedding dress hems, ballet skirts, haute couture gowns, window curtains, and stage sets that require a magical atmosphere.

Type 7: Glitter Vinyl Fabric

Glitter vinyl fabric is a synthetic leather with a highly reflective metallic sheen, achieved through the incorporation of glitter particles (such as sequins or metallic powder) or a special gloss treatment. Its structure typically consists of a fiber base (such as a knitted or non-woven fabric) topped with a thick, glitter-infused PVC/PU coating. This coating not only imparts the fabric with its signature slippery feel and intense mirrored finish, but also provides an excellent waterproof barrier, making it an industrial material that seamlessly combines decorative and functional qualities.

Main Benefits of Glitter Vinyl Fabric

Extreme Visual Impact and Futuristic Aura: Its most prominent advantage is its ability to produce an intense, highly reflective mirrored or metallic sheen. This instantly recognizable look makes it a popular choice for sci-fi, avant-garde, and cyberpunk styles, creating a visually striking and instantly captivating look.

Excellent Waterproofing and Easy Cleaning: Thanks to its dense, non-porous PVC/PU coating, this fabric is 100% waterproof and impermeable to liquids. Stains can be removed with a simple wipe of a damp cloth, making maintenance extremely easy and ideal for use in environments requiring high hygiene standards or for outdoor furniture.

Durability and Cost-Effectiveness: This fabric is exceptionally tough, abrasion-resistant, and tear-resistant, and its color resists fading from sunlight, ensuring a long lifespan. Furthermore, as a synthetic leather, its production cost is significantly lower than genuine leather, enabling it to achieve a high-end visual effect at a relatively low price. This highly cost-effective material is widely used in fashion footwear, prop production, furniture upholstery, and automotive interiors.

Post time: Sep-30-2025