Chapter 1: Definition and Core Concepts—What is Water-Based PU Leather?

Water-based PU leather, also known as water-based polyurethane synthetic leather, is a high-grade artificial leather made by coating or impregnating a base fabric with a polyurethane resin using water as a dispersion medium (diluent). To understand its value, we first need to break down the term:

Polyurethane (PU): This is a high-molecular polymer with excellent abrasion resistance, flexibility, high elasticity, and aging resistance. It is the core raw material for synthetic leather, and its properties directly determine the leather's texture, feel, and durability.

Water-based: This is the key difference from traditional processes. It refers to the fact that the polyurethane resin is not dissolved in an organic solvent (such as DMF, toluene, or butanone), but is instead uniformly dispersed in water as tiny particles, forming an emulsion.

Thus, water-based PU leather is essentially an environmentally friendly artificial leather produced using polyurethane technology using water as a solvent. Its emergence and development represents a significant technological leap forward for the leather industry in response to global environmental protection trends and health and safety demands.

Chapter 2: Background - Why Water-Based PU Leather?

The emergence of water-based PU leather was no accident; it was designed to address the serious problems presented by traditional solvent-based PU leather.

1. Disadvantages of Traditional Solvent-Based PU Leather:

Serious Environmental Pollution: During the production process, large amounts of volatile organic compounds (VOCs) are emitted into the atmosphere. VOCs are important precursors to photochemical smog and PM2.5, posing significant risks to the environment and human health.

Health and Safety Hazards: Organic solvents are often toxic, flammable, and explosive. Long-term exposure to factory workers poses a risk of poisoning, and small amounts of solvent residue may remain in the finished product during its initial stage, posing a potential health threat to consumers.

Resource Waste: Solvent-based processes require complex recovery equipment to recycle and process these organic solvents, resulting in high energy consumption and the inability to achieve 100% recovery, resulting in resource waste.

2. Policy and Market Drivers:

Tightening Global Environmental Regulations: Countries around the world, particularly China, the EU, and North America, have introduced extremely stringent VOC emission limits and environmental tax laws, forcing industrial upgrading.

Consumer environmental awareness is rising: More and more brands and consumers are considering "environmental protection," "sustainability," and "green" as important factors in their purchasing decisions, leading to a growing demand for clean materials.

Corporate Social Responsibility (CSR) and Brand Image: Using environmentally friendly materials has become an effective way for companies to fulfill their social responsibilities and enhance their brand reputation.

Driven by these factors, water-based PU technology, as the most viable alternative, presents tremendous development opportunities.

Chapter 3: Manufacturing Process - The Core Differences Between Water-Based and Solvent-Based Leather

The manufacturing process for water-based PU leather is largely similar to that of solvent-based, primarily including base fabric preparation, polyurethane coating, curing, washing, drying, and surface treatment (embossing, printing, and rubbing). The key differences lie in the "coating" and "curing" stages.

1. Solvent-Based Process (DMF System):

Coating: The PU resin is dissolved in an organic solvent such as DMF (dimethylformamide) to form a viscous solution, which is then applied to the base fabric.

Coagulation: The coated semi-finished product is immersed in a water-based coagulation bath. Leveraging the infinite miscibility of DMF and water, DMF rapidly diffuses from the PU solution into the water, while the water permeates the PU solution. This process causes the PU to precipitate from the solution, forming a microporous cortical layer. DMF wastewater requires expensive distillation and recovery equipment.

2. Water-based Process:

Coating: A water-based PU emulsion (PU particles dispersed in water) is applied to the base fabric through methods such as knife coating or dipping.

Coagulation: This is a technically challenging process. Water-based emulsions do not contain solvents such as DMF, so coagulation cannot be simply performed with water. Currently, there are two mainstream coagulation methods:

Thermal coagulation: Heat and drying are used to evaporate the water, causing the water-based PU particles to melt and form a film. This method creates a dense film with poor air permeability.

Coagulation (chemical coagulation): This is the key to producing breathable water-based leather. After coating, the material passes through a bath containing a coagulant (usually an aqueous solution of a salt or organic acid). The coagulant destabilizes the aqueous emulsion, forcing the PU particles to break up, aggregate, and settle, resulting in a microporous structure similar to that of solvent-based materials. This provides excellent air and moisture permeability.

The water-based process completely eliminates organic solvents, eliminating VOC emissions at the source. This makes the entire production environment safer and eliminates the need for complex solvent recovery systems, resulting in a simpler and more environmentally friendly process.

Chapter 4: Performance Characteristics - Advantages and Disadvantages of Water-Based PU Leather

(I) Core Advantages:

Ultimate Environmental Protection:

Near-Zero VOC Emissions: No toxic or hazardous organic solvents are emitted during the production process, resulting in environmentally friendly performance.

Non-Toxic and Harmless: The final product contains no residual solvents, is non-irritating to human skin, and is safe and non-toxic. It complies with the most stringent environmental standards (such as EU REACH and OEKO-TEX Standard 100), making it ideal for applications requiring high health standards, such as infant and toddler products, automotive interiors, and home furnishings.

Safer production process: Eliminates the risks of fire, explosion, and worker poisoning.

Excellent Performance:

Excellent Handfeel: Leather made with water-based PU resin typically has a softer, fuller feel, closer to genuine leather.

Breathable and Moisture-Permeable (for Coagulation): The microporous structure created allows air and moisture to pass through, making shoes, bags, sofas, and other products dryer and more comfortable to use, overcoming the stuffiness often associated with artificial leather.

High Hydrolysis Resistance: One inherent weakness of polyurethane is its susceptibility to hydrolysis and degradation in high-temperature and high-humidity environments. Water-based PU systems generally offer better control over their molecular structure, resulting in superior hydrolysis resistance compared to comparable solvent-based PU leather, resulting in a longer service life.

Strong Adhesion: Water-based resins exhibit excellent wettability and adhesion to a variety of substrates (non-woven, woven, and microfiber-based fabrics).

Policy and Market Advantages:

Easily meet domestic and international environmental regulations, ensuring worry-free export.

With the "Green Product" label, it's easier to find purchase on the shopping lists of high-end brands and consumers.

Chapter 5: Application Areas - A Ubiquitous Eco-Friendly Choice

Leveraging its dual advantages of environmental friendliness and performance, water-based PU leather is rapidly penetrating various sectors:

Apparel and Footwear: Athletic shoe uppers, casual shoes, fashion shoes, leather garments, down jacket trims, backpacks, and more are its largest applications. Breathability and comfort are key.

Furniture and Home Furnishings: High-end sofas, dining chairs, bedside covers, and interior soft furnishings. These applications demand extremely high levels of hydrolysis resistance, abrasion resistance, and environmental safety.

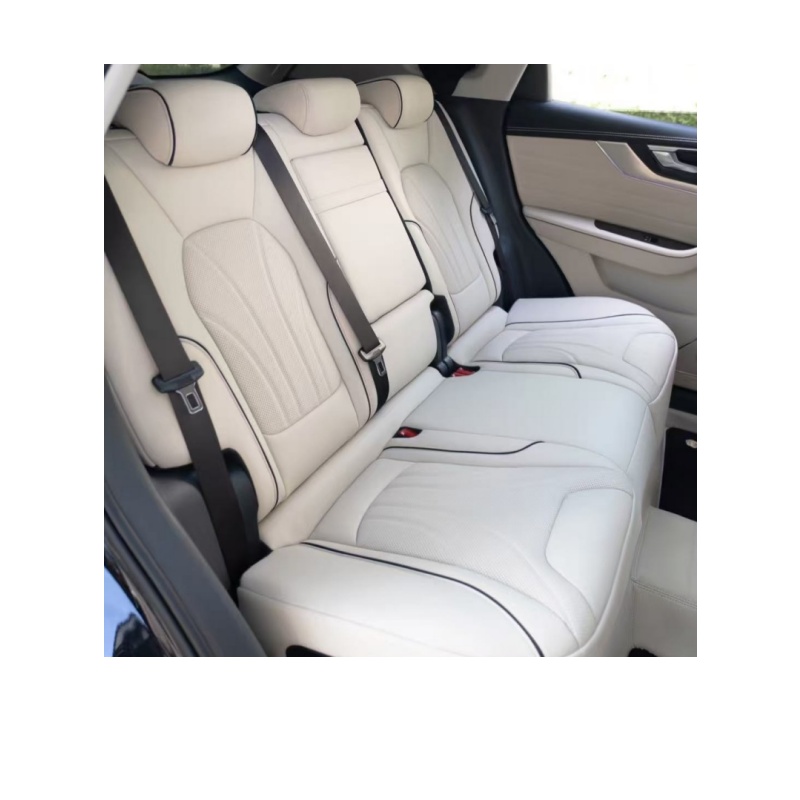

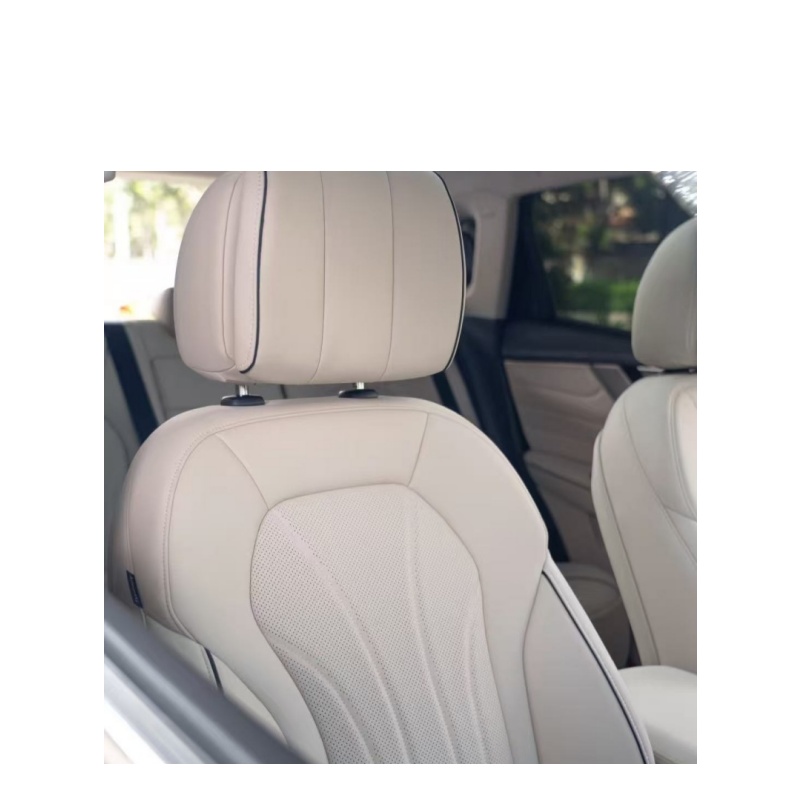

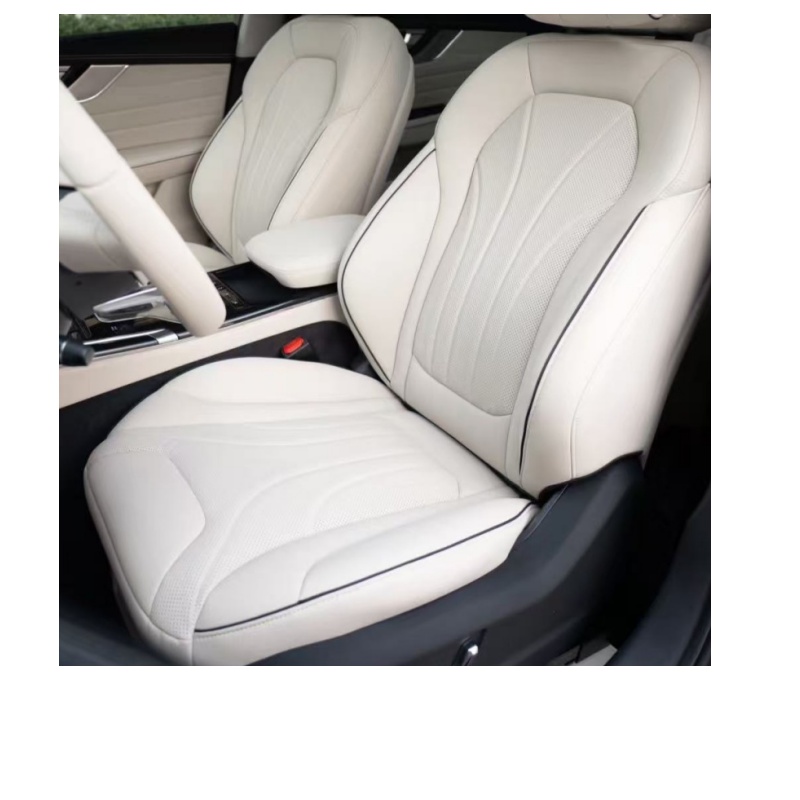

Automotive Interiors: Car seats, armrests, door panels, steering wheel covers, and more. This is a key market for high-end water-based PU leather, which must meet stringent standards for aging resistance, light resistance, low VOCs, and flame retardancy.

Electronic Products: Laptop cases, headphone cases, smartwatch straps, and more, offering a gentle, skin-friendly, and stylish feel.

Luggage and Handbags: Fabrics for various fashionable handbags, briefcases, and luggage, combining aesthetics, durability, and lightweight design.

Sporting Goods: Footballs, basketballs, gloves, and more.

Chapter 6: Comparison with Other Materials

vs. Solvent-Based PU Leather: As mentioned above, water-based leather is superior in terms of environmental friendliness, healthiness, and hand feel, but it still has room to catch up in terms of cost and some extreme performance. Water-based leather is the clear technological development direction.

vs. Genuine Leather: Genuine leather is a natural material with a unique texture and superior breathability, but it is expensive, has uneven quality, and the production process (tanning) is polluting. Water-based PU leather offers consistent appearance and performance at a lower cost, without harming animals, and is more aligned with sustainable ethical consumption concepts.

vs. PVC Artificial Leather: PVC leather offers the lowest price, but it has a hard feel, poor breathability, is not cold-resistant, and may pose environmental issues due to the addition of plasticizers. Water-based PU leather surpasses PVC in terms of performance and environmental friendliness.

vs. Microfiber Leather: Microfiber leather is a premium synthetic leather with performance closest to genuine leather. It typically uses a microfiber non-woven fabric as its backing, and the coating can be made of either solvent-based or water-based PU. The combination of high-end water-based PU and microfiber fabric represents the pinnacle of current artificial leather technology.

Chapter 6: Future Development Trends

Technological Iteration and Performance Breakthroughs: By developing new water-based resins (such as silicone-modified PU and acrylic-modified PU) and optimizing curing technology, the product's physical properties and functionalization (flame retardancy, antibacterial properties, self-healing, etc.) will be further enhanced.

Cost Optimization and Scalability: With the popularization of technology and expansion of production capacity, economies of scale will gradually reduce the overall cost of water-based PU leather, making it more competitive in the market.

Industry Chain Integration and Standardization: From resin synthesis to tannery manufacturing to brand application, the entire industry chain will form closer collaboration and jointly promote the establishment and improvement of industry standards.

Circular Economy and Bio-based Materials: Future research and development will focus not only on the production process, but also on the recyclability and biodegradability of products after their end-of-life cycle. The use of bio-based raw materials (such as corn and castor oil) to prepare water-based PU resins will be the next frontier.

Conclusion

Water-based PU leather is more than just a simple material replacement; it represents the core path for the leather industry to transform from a traditional, highly polluting, and energy-intensive model to a green, sustainable one. It successfully strikes a valuable balance between performance, cost, and environmental friendliness, satisfying consumer demand for high-quality leather products while also fulfilling corporate social responsibility to protect the environment. While currently facing some cost and technical challenges, its enormous environmental advantages and potential for application make it an irreversible industry trend. As the technology matures and market awareness deepens, water-based PU leather is poised to become the undisputed mainstream of the future artificial leather market, creating a cleaner, safer, and more fashionable "leather" world.

Post time: Sep-10-2025