Historical Origins and Basic Definitions: Two Different Technological Paths

To understand the difference between the two, we first need to trace their development histories, which determine their fundamental technological logic.

1. PVC Leather: The Pioneer of Synthetic Leather

The history of PVC leather dates back to the 19th century. Polyvinyl chloride (PVC), a polymer material, was discovered as early as 1835 by French chemist Henri Victor Regnault and industrialized by the German company Griesheim-Elektron in the early 20th century. However, its true application in leather imitation didn't begin until World War II.

The war led to resource shortages, particularly natural leather. Natural leather was primarily supplied to the military, leaving the civilian market severely depleted. This significant demand gap spurred the development of alternatives. Germans pioneered the use of PVC coated on a fabric base, creating the world's first artificial leather. This material, with its excellent water resistance, durability, and easy cleanability, quickly gained application in areas such as luggage and shoe soles.

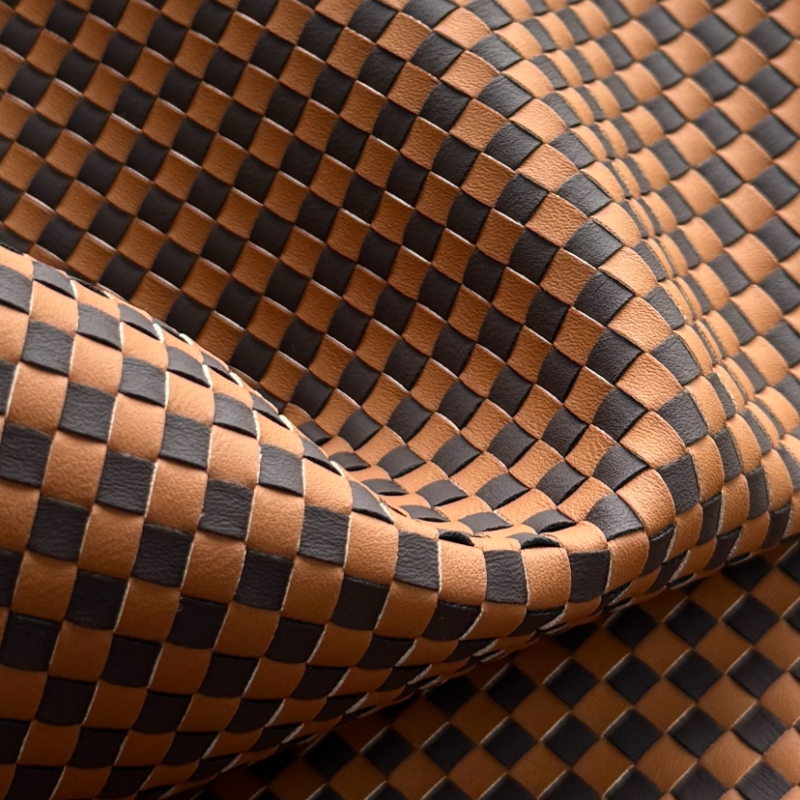

Basic Definition: PVC leather is a leather-like material made by coating or calendering a layer of a paste-like resin mixture of polyvinyl chloride resin, plasticizers, stabilizers, and pigments onto a fabric substrate (such as knitted, woven, and non-woven fabrics). The material then undergoes processes such as gelation, foaming, embossing, and surface treatment. The core of this process lies in the use of polyvinyl chloride resin.

2. PU Leather: A Newcomer Closer to Genuine Leather

PU leather emerged approximately two decades after PVC. Polyurethane (PU) chemistry was invented by German chemist Otto Bayer and his colleagues in 1937 and rapidly developed after World War II. Advances in chemical technology in the 1950s and 1960s led to the development of synthetic leather using polyurethane.

PU synthetic leather technology experienced rapid advancements in Japan and South Korea in the 1970s. In particular, Japanese companies have developed microfiber fabrics (abbreviated as "microfiber leather") with a microstructure that closely resembles genuine leather. Combining this with polyurethane impregnation and coating processes, they have produced "microfiber PU leather," whose performance closely resembles genuine leather and even surpasses it in some aspects. This is considered a revolution in synthetic leather technology.

Basic Definition: PU leather is a leather-like material made from a fabric base (regular or microfiber), coated or impregnated with a layer of polyurethane resin, followed by drying, solidification, and surface treatment. The core of this process lies in the application of polyurethane resin. PU resin is inherently thermoplastic, allowing for more flexible processing and superior product performance.

Summary: Historically, PVC leather originated as a "wartime emergency supply," resolving the issue of availability. PU leather, on the other hand, is the product of technological advancement, aiming to address the issue of quality and pursue a near-identical look at genuine leather. This historical foundation has profoundly influenced the subsequent development paths and product characteristics of both.

II. Core Chemical Composition and Production Process: The Root of the Difference

The most fundamental difference between the two lies in their resin systems, which, like their "genetic code," determine all subsequent properties.

1. Chemical Composition Comparison

PVC (Polyvinyl Chloride):

Main component: Polyvinyl chloride resin powder. This is a polar, amorphous polymer that is inherently very hard and brittle.

Key Additives:

Plasticizer: This is the "soul" of PVC leather. To make it flexible and processable, large amounts of plasticizers (typically 30% to 60% by weight) must be added. Plasticizers are small molecules that embed between the PVC macromolecule chains, weakening intermolecular forces and thereby increasing the material's flexibility and plasticity. Commonly used plasticizers include phthalates (such as DOP and DBP) and environmentally friendly plasticizers (such as DOTP and citrate esters).

Heat Stabilizer: PVC is thermally unstable and readily decomposes at processing temperatures, releasing hydrogen chloride (HCl), causing the material to yellow and degrade. Stabilizers such as lead salts and calcium zinc are necessary to inhibit decomposition. Others: Also includes lubricants, fillers, pigments, etc.

PU (Polyurethane):

Main component: Polyurethane resin. It is made through the polymerization reaction of polyisocyanates (such as MDI, TDI) and polyols (polyester polyols or polyether polyols). By adjusting the raw material formula and ratio, the final product's properties, such as hardness, elasticity, and wear resistance, can be precisely controlled.

Key Features: PU resin can be inherently soft and elastic, typically requiring no or minimal addition of plasticizers. This makes PU leather's composition relatively simpler and more stable.

Direct Impact of Chemical Differences: PVC's heavy reliance on plasticizers is the root cause of many of its shortcomings (such as a hard feel, brittleness, and environmental concerns). PU, on the other hand, is directly "engineered" to deliver the desired properties through chemical synthesis, eliminating the need for small molecule additives. Consequently, its performance is superior and more stable.

2. Production Process Comparison

The production process is key to achieving its performance. While the two processes are similar, the core principles differ. PVC leather production process (using coating as an example):

Ingredients: PVC powder, plasticizer, stabilizer, pigment, etc. are mixed in a high-speed mixer to form a uniform paste.

Coating: The PVC paste is evenly applied to the base fabric using a spatula.

Gelation/Plasticization: The coated material enters a high-temperature oven (typically 170-200°C). Under high temperatures, the PVC resin particles absorb the plasticizer and melt, forming a continuous, uniform film layer that firmly bonds to the base fabric. This process is called "gelation" or "plasticization."

Surface Treatment: After cooling, the material is passed through an embossing roller to impart various leather textures (such as lychee grain and sheepskin grain). Finally, a surface finish is typically applied, such as a spray-on PU lacquer (i.e., PVC/PU composite leather) to improve the feel and wear resistance, or printing and coloring. PU leather production process (using wet and dry processes as examples):

The production process for PU leather is more complex and sophisticated, and there are two main methods:

Dry-process PU leather:

Polyurethane resin is dissolved in a solvent such as DMF (dimethylformamide) to form a slurry.

The slurry is then applied to a release liner (a special paper with a patterned surface).

Heating evaporates the solvent, causing the polyurethane to solidify into a film, forming the pattern on the release liner.

The other side is then laminated to a base fabric. After aging, the release liner is peeled off, resulting in PU leather with a delicate pattern.

Wet-process PU leather (basic):

Polyurethane resin slurry is applied directly to the base fabric.

The fabric is then immersed in water (DMF and water are miscible). The water acts as a coagulant, extracting the DMF from the slurry, causing the polyurethane resin to solidify and precipitate. During this process, polyurethane forms a porous microsphere-like structure filled with gas, giving wet-laid leather excellent moisture and breathability, and a very soft and plump feel, remarkably similar to genuine leather.

The resulting wet-laid leather semi-finished product typically undergoes a dry-laid process for fine surface treatment.

Direct Impact of Process Differences: PVC leather is simply formed by physical melt molding, resulting in a dense structure. PU leather, particularly through the wet-laid process, develops a porous, interconnected sponge structure. This is the key technical advantage that makes PU leather far superior to PVC in terms of breathability and feel.

III. Comprehensive Performance Comparison: Clearly Determine Which is Better

Due to different chemistries and production processes, PVC and PU leather exhibit significant differences in their physical properties.

- Feel and Softness:

- PU leather: Soft and elastic, it conforms to the body's curves better, giving it a feel similar to genuine leather.

- PVC leather: Relatively hard and lacking in elasticity, it easily creases when bent, giving it a plastic-like feel. - Breathability and Moisture Permeability:

- PU Leather: Offers excellent breathability and moisture permeability, keeping the skin relatively dry during wear and use, reducing the feeling of stuffiness.

- PVC Leather: Offers poor breathability and moisture permeability, which can easily cause sweating, dampness, and discomfort after prolonged use or wear.

- Abrasion and Folding Resistance:

- PU Leather: Offers excellent abrasion and folding resistance, withstanding a certain degree of friction and bending, and is not susceptible to wear or cracking.

- PVC Leather: Offers relatively poor abrasion and folding resistance, and is prone to wear and cracking after long-term use, especially in areas subject to frequent folding and friction.

- Hydrolysis Resistance:

- PU Leather: Offers poor hydrolysis resistance, especially polyester-based PU leather, which is prone to hydrolysis in humid environments, resulting in a degradation of material properties.

- PVC Leather: Offers excellent hydrolysis resistance, is highly adaptable to humid environments, and is not easily damaged by hydrolysis. - Temperature Resistance:

- PU Leather: It tends to stick at high temperatures and harden at low temperatures. It is sensitive to temperature fluctuations and has a relatively narrow operating temperature range.

- PVC Leather: It has better temperature resistance and maintains relatively stable performance over a wide temperature range, but it also has the risk of brittleness at low temperatures.

- Environmental Performance:

- PU Leather: It is more biodegradable than PVC leather. Some products may contain small amounts of organic solvent residues, such as DMF, during the production process, but its overall environmental performance is relatively good.

- PVC Leather: It is less environmentally friendly, containing chlorine. Some products may contain harmful substances such as heavy metals. During production and use, it may release harmful gases, which may have certain impacts on the environment and human health.

Appearance and Color

- PU Leather: It comes in a wide variety of vibrant colors, with good color stability and is not easy to fade. Its surface texture and pattern are diverse, and it can imitate various leather textures, such as cowhide and sheepskin, and can also be created with unique patterns and designs to meet different design needs. - PVC leather: Also available in a wide range of colors, but slightly inferior to PU leather in terms of color vividness and stability. Its surface texture is relatively simple, typically smooth or with simple embossing, making it difficult to achieve the highly realistic look of PU leather.

Lifespan

- PU leather: Its lifespan is generally 2-5 years, depending on the environment and frequency of use. With normal use and maintenance, PU leather products maintain their excellent appearance and performance.

- PVC leather: Its lifespan is relatively short, typically 2-3 years. Due to its poor durability, it is prone to aging and damage with frequent use or harsh environments.

Cost and Price

- PU leather: Its cost is higher than PVC leather, approximately 30%-50% higher. Its price varies depending on factors such as production process, raw material quality, and brand. Generally, mid- to high-end PU leather products are more expensive.

- PVC leather: Its cost is relatively low, making it one of the most affordable synthetic leathers on the market. Its price advantage makes it widely used in cost-sensitive products.

Performance Summary:

PVC leather's advantages include high wear resistance, high hardness, extremely low cost, and a simple production process. It is an excellent "functional material."

PU leather's advantages include a soft feel, breathability, moisture permeability, cold and aging resistance, excellent physical properties, and environmental friendliness. It is an excellent "experience material," focused on mimicking and surpassing the sensory properties of genuine leather.

IV. Application Scenario: Differentiation by Performance

Based on the above performance characteristics, the two naturally have different positioning and divisions of labor in the application market. Main Applications of PVC Leather:

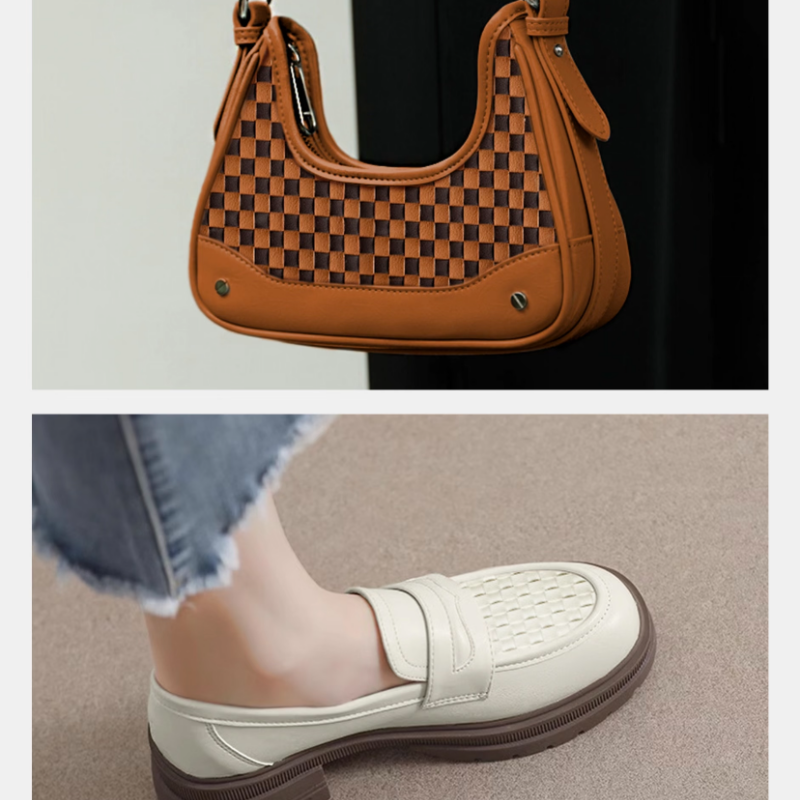

Luggage and Handbags: Especially hard cases and handbags that require a fixed shape, as well as travel bags and backpacks that require wear resistance.

Shoe Materials: Primarily used in non-contact areas such as soles, upper trims, and linings, as well as low-end rain boots and work shoes.

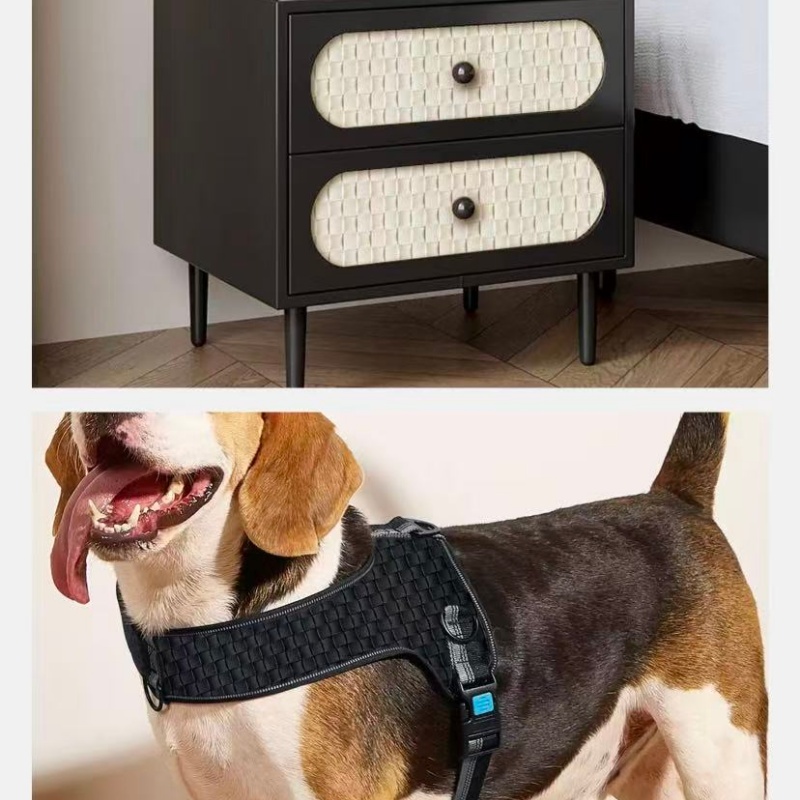

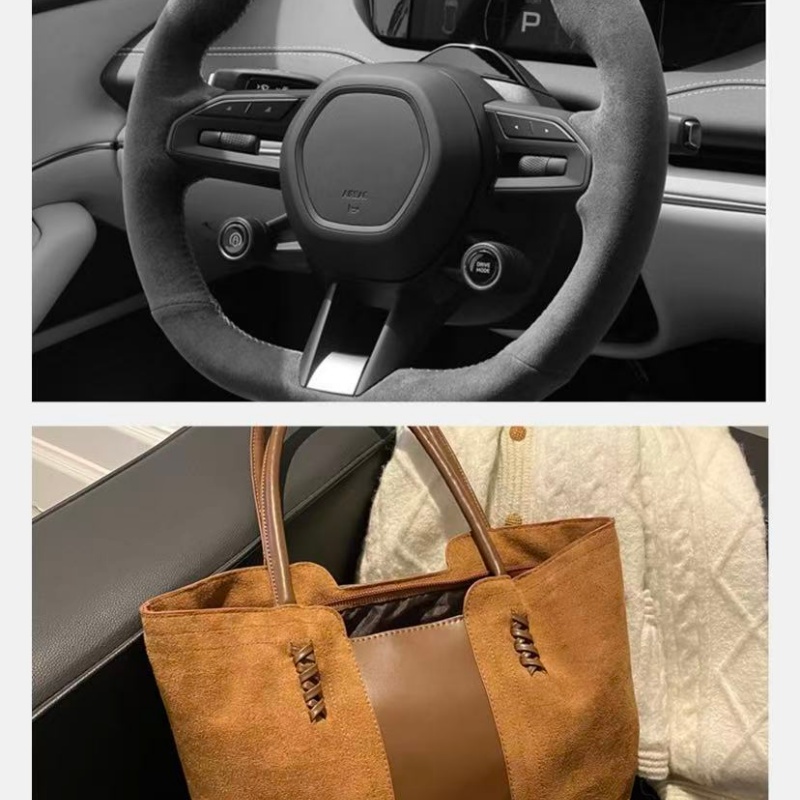

Furniture and Decoration: Used on non-contact surfaces such as the backs, sides, and bottoms of sofas and chairs, as well as in public transportation (bus and subway) seats, where its extremely high wear resistance and low cost are valued. Wall coverings, floor coverings, etc. Automotive Interiors: Gradually being replaced by PU, it is still used in some low-end models or in less important areas such as door panels and trunk mats.

Industrial Products: Tool bags, protective covers, instrument covers, etc.

Main Applications of PU Leather:

Shoe Materials: The absolute main market. Used in the uppers of sneakers, casual shoes, and leather shoes because it provides excellent breathability, softness, and a stylish look.

Apparel and Fashion: Leather jackets, leather pants, leather skirts, gloves, etc. Its excellent drape and comfort make it a favorite in the clothing industry.

Furniture and Home Furnishings: High-end synthetic leather sofas, dining chairs, bedside tables, and other areas that come into direct contact with the body. Microfiber PU leather is widely used in luxury car seats, steering wheels, and dashboards, providing a near-real leather experience.

Luggage and Accessories: High-end handbags, wallets, belts, etc. Its exquisite texture and feel can create a realistic effect.

Electronic Product Packaging: Used in laptop bags, headphone cases, glasses cases, etc., balancing protection and aesthetics.

Market Positioning:

PVC leather firmly holds a firm position in the low-end market and in industrial sectors requiring extreme wear resistance. Its price-performance ratio is unmatched.

PU leather, on the other hand, dominates the mid-to-high-end market and continues to challenge the high-end market previously dominated by genuine leather. It is a mainstream choice for consumer upgrades and as an alternative to genuine leather.

V. Price and Market Trends

Price:

The production cost of PVC leather is significantly lower than that of PU leather. This is primarily due to the low prices of raw materials such as PVC resin and plasticizers, as well as the low energy consumption and simple production process. As a result, the price of finished PVC leather is typically only half or even one-third of that of PU leather.

Market Trends:

PU leather continues to expand, while PVC leather maintains a steady decline: Globally, especially in developed countries, PU leather is steadily eroding PVC leather's traditional market share due to increasingly stringent environmental regulations (such as the EU REACH regulation restricting phthalates) and increasing consumer demands for product quality and comfort. PVC leather's growth is primarily concentrated in developing countries and in extremely cost-sensitive sectors. Environmental protection and sustainable development have become core driving forces:

Bio-based PU, water-based PU (solvent-free), plasticizer-free PVC, and eco-friendly plasticizers have become research and development hotspots. Brand owners are also increasingly prioritizing the recyclability of materials.

Microfiber PU leather (microfiber leather) is the future trend:

Microfiber leather utilizes a microfiber base fabric with a structure similar to the collagen fibers of genuine leather, offering performance that approaches or even surpasses genuine leather. It is known as the "third generation of artificial leather." It represents the pinnacle of synthetic leather technology and is a key development direction for the high-end market. It is widely used in high-end automotive interiors, sports shoes, luxury goods, and other fields.

Functional Innovation:

Both PVC and PU are developing functional features such as antibacterial, mildew-proof, flame-retardant, UV-resistant, and hydrolysis-resistant to meet the demanding requirements of specific applications.

VI. How to Distinguish PVC Leather from PU Leather

For consumers and purchasers, mastering simple identification methods is very practical.

Combustion Method (Most Accurate):

PVC Leather: Difficult to ignite, extinguishes immediately when removed from flame. The base of the flame is green and has a strong, pungent smell of hydrochloric acid (like burning plastic). It hardens and blackens after burning.

PU leather: Flammable, with a yellow flame. It has an odor similar to wool or burning paper (due to the presence of ester and amino groups). It softens and becomes sticky after burning.

Note: This method may outlook

PVC leather and PU leather aren't simply a matter of "good" versus "bad." Instead, they are two products developed based on the needs of different eras and technological advancements, each with its own rationale and potential applications.

PVC leather represents the ultimate balance between cost and durability. It remains resilient in applications where comfort and environmental performance are less critical, but where wear resistance, water resistance, and low cost are paramount. Its future lies in addressing its inherent environmental and health risks through environmentally friendly plasticizers and technological advancements, thereby maintaining its position as a functional material.

PU leather is a superior choice for comfort and environmental protection. It represents the mainstream development of synthetic leather. Through continuous technological innovation, it has surpassed PVC in terms of feel, breathability, physical properties, and environmental performance, becoming a key alternative to genuine leather and enhancing the quality of consumer goods. Microfiber PU leather, in particular, is blurring the lines between synthetic and genuine leather, opening up new high-end applications.

When choosing a product, consumers and manufacturers should not simply compare price but make a comprehensive judgment based on the product's end use, regulatory requirements in the target market, the brand's environmental commitment, and user experience. Only by understanding their underlying differences can we make the wisest and most appropriate choice. In the future, as materials technology advances, we may see "fourth- and fifth-generation" artificial leathers with even better performance and greater environmental friendliness. However, the more than half-century-long rivalry and complementary nature of PVC and PU will remain a fascinating chapter in the history of materials development.

Post time: Sep-12-2025