The PVC floor calendering method is an efficient and continuous production process, which is particularly suitable for the production of homogeneous and permeable structure sheets (such as commercial homogeneous permeable flooring). Its core is to plasticize the molten PVC into a uniform thin layer through a multi-roll calender, and then cool it to shape. The following are the specific steps and key technical control points:

I. Calendering Process

Raw Material Pretreatment > High-speed hot mixing, cooling and cold mixing, internal mixing and plasticizing, open mixing and feeding

Four-roll calendering, embossing/laminating, cooling and shaping, trimming and winding

II. Step-by-step Operation Key Points and Technical Parameters

1. Raw Material Pretreatment and Mixing

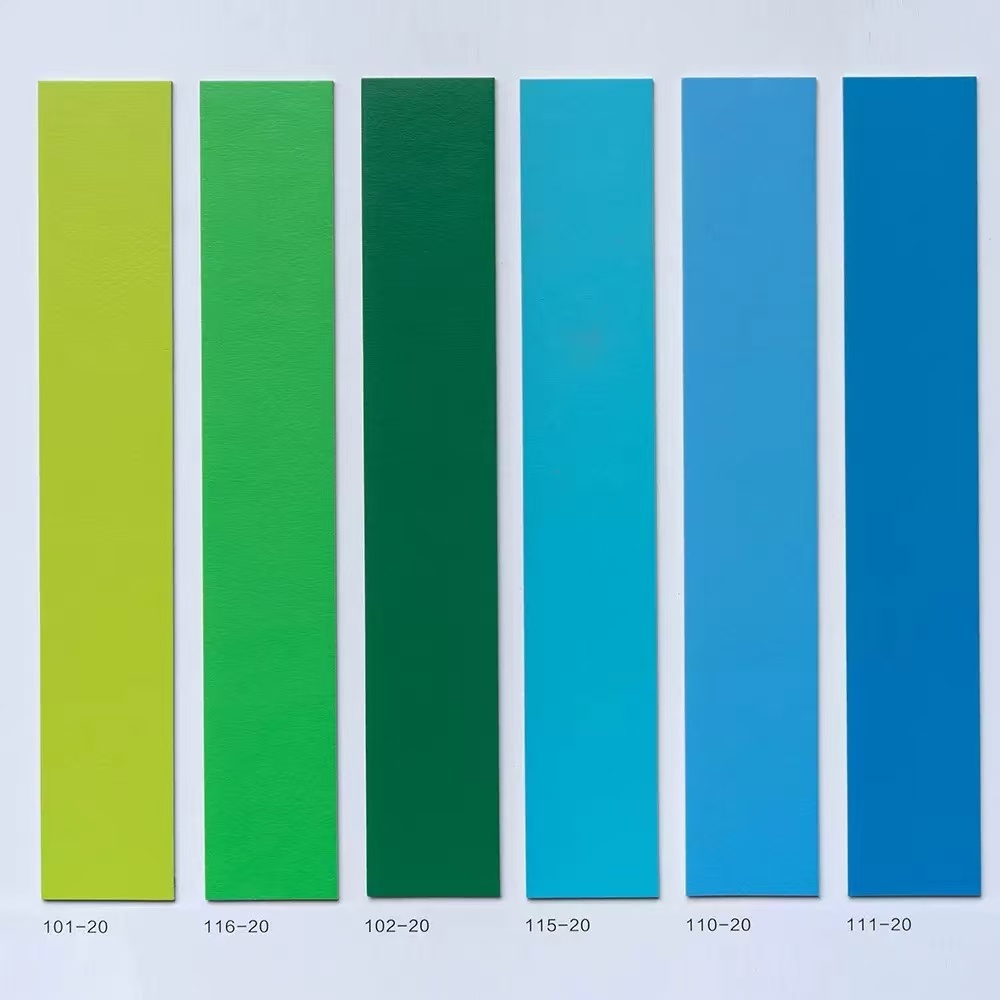

Formula Composition (Example): - PVC resin (S-70 type) 100 parts, - Plasticizer (DINP/environmentally friendly ester) 40-60 parts, - Calcium carbonate filler (1250 mesh) 50-80 parts, - Heat stabilizer (calcium zinc composite) 3-5 parts, - Lubricant (stearic acid) 0.5-1 part, - Pigment (titanium dioxide/inorganic color powder) 2-10 parts

Mixing Process*:

Hot mixing: High-speed mixer (≥1000 rpm), heat to 120°C (10-15 minutes) to allow the PVC to absorb the plasticizer; Cold Mixing: Rapidly cool to below 40°C (to prevent lumps), cold mixing time ≤ 8 minutes.

2. Plasticizing and Feeding

- Internal Mixer: Temperature 160-170°C, Pressure 12-15 MPa, Time 4-6 minutes → Forming a homogeneous rubber mass;

Open Mixer: Twin-roll temperature 165±5°C, Roller Gap 3-5 mm → Cut into strips for continuous feeding to the calender.

3. Four-roller Calendering (Core Process)

- Key Techniques:

- Roller Speed Ratio: 1#:2#:3#:4# = 1:1.1:1.05:1.0 (to prevent material accumulation);

- Mid-Height Compensation: Roller 2 is designed with a 0.02-0.05mm crown to offset thermal bending deformation. 4. Surface Treatment and Lamination

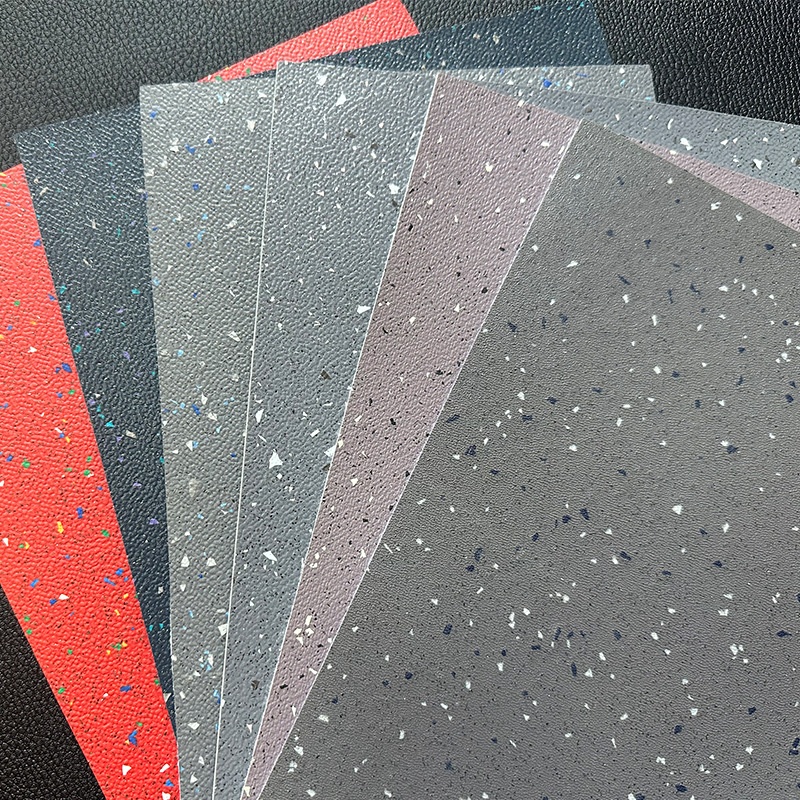

Embossing: Embossing roller (silicone/steel) temperature 140-150°C, pressure 0.5-1.0 MPa, speed matched to the calendering line;

Substrate Lamination (Optional): Glass fiber mat/non-woven fabric, preheated (100°C), is laminated with the PVC melt at roller #3 to enhance dimensional stability.

5. Cooling and Shaping

Three-stage cooling roller temperature:

Tension Control: Winding tension 10-15 N/mm² (to prevent cold shrinkage and deformation).

6. Trimming and Winding

- Laser Online Thickness Measurement: Real-time feedback adjusts the roller gap (accuracy ±0.01mm);

- Automatic Trimming: Scrap width ≤ 20mm, recycled and pelletized for reuse;

- Winding: Constant tension center winding, roll diameter Φ800-1200mm. III. Process Difficulties and Solutions

1. Uneven Thickness. Cause: Roller Temperature Fluctuation > ±2°C. Solution: Closed-Loop Thermal Oil Temperature Control + Close-Drilled Roller Cooling.

2. Surface Gas. Cause: Insufficient Mixing Degassing. Solution: Vacuum the Internal Mixer (-0.08 MPa).

3. Edge Cracks. Cause: Excessive Cooling/Excessive Tension. Solution: Reduce the Front-End Cooling Intensity and Add a Slow Cooling Zone.

4. Pattern Die. Cause: Insufficient Embossing Roller Pressure. Solution: Increase the Hydraulic Pressure to 1.2 MPa and Clean the Roller Surface.

IV. Environmentally Friendly and Performance Upgraded Processes

1. Lead-Free Stabilizer Replacement:

- Calcium-Zinc Composite Stabilizer + β-Diketone Synergist → Passes EN 14372 Migration Test;

2. Environmentally Friendly Plasticizer:

- DINP (Diisononyl Phthalate) → Cyclohexane 1,2-Dicarboxylate (Ecoflex®) Reduces Ecotoxicity.

3. Waste Recycling:

- Crushing scraps → Blending with new material at a ratio of ≤30% → Used in base layer production.

V. Calendering vs. Extrusion (Application Comparison)

Product Structure: Homogeneous perforated flooring/Multi-layer composite, Multi-layer co-extrusion (wear-resistant layer + foam layer)

Thickness Range: 1.5-4.0mm (Accuracy ±0.1mm), 3.0-8.0mm (Accuracy ±0.3mm)

Surface Finish: High gloss/Precision embossing (wood grain imitation), Matte/Rough texture

Typical Applications: Homogeneous perforated flooring in hospitals and laboratories, SPC interlocking flooring for homes

Summary: The core value of the calendering method lies in "high precision" and "high consistency"

- Process Advantages:

- Precision roller temperature control → Thickness variation coefficient <1.5%;

- In-line embossing and lamination → Achieve stone/metal visual effects;

- Applicable Products:

Homogeneous perforated PVC flooring with high dimensional stability requirements (such as the Tarkett Omnisports series);

- Upgrade Options:

- Intelligent Control: AI-powered dynamic roller gap adjustment (real-time thickness feedback);

- Energy Recovery: Cooling water waste heat is used for raw material preheating (saving 30% energy).

> Note: In actual production, the calendering temperature and roller speed should be adjusted according to the formula fluidity (melt index MFI = 3-8g/10min) to avoid degradation (yellowing index ΔYI < 2).

Post time: Jul-30-2025