Chapter 1: Concept Definition – Definition and Scope

1.1 PU Leather: Classic Chemically Based Synthetic Leather

Definition: PU leather, or polyurethane synthetic leather, is a man-made material made with a polyurethane (PU) resin as a surface coating, attached to various substrates (most commonly polyester or cotton). It is a specific, technically defined chemical product.

Core Identity: It is a technical term that clearly identifies the material's chemical composition (polyurethane) and structure (coated composite material).

1.2 Vegan Leather: An Ethically Based Consumer Choice

Definition: Vegan leather is a marketing and ethical term, not a technical one. It refers to any leather alternative material that uses no animal ingredients or by-products. Its core motivation lies in avoiding harm and exploitation of animals.

Core Identity: It is an umbrella term representing a product category that adheres to vegan principles. Its scope is very broad; as long as it meets the ethical standard of "animal-free," any leather can be considered vegan, regardless of whether its base material is a chemical polymer or a plant-based material. 1.3 Key Difference: Technology vs. Ethics

This is the cornerstone of understanding the difference between the two. PU leather tells you "what it is made of," while vegan leather tells you "what it lacks and why it's made."

Chapter 2: Manufacturing Process and Material Sources—From Molecules to Materials

2.1 PU Leather Manufacturing: A Product of the Petrochemical Industry

PU leather manufacturing is a complex chemical process, derived from fossil fuels (petroleum).

Substrate Preparation: First, a fabric substrate, typically polyester or cotton, is prepared, cleaned, and treated.

Slurry Preparation: Polyurethane particles are dissolved in a solvent (traditionally DMF-dimethylformamide, but increasingly, water-based solvents) and colorants, additives, and other additives are added to form a mixed slurry.

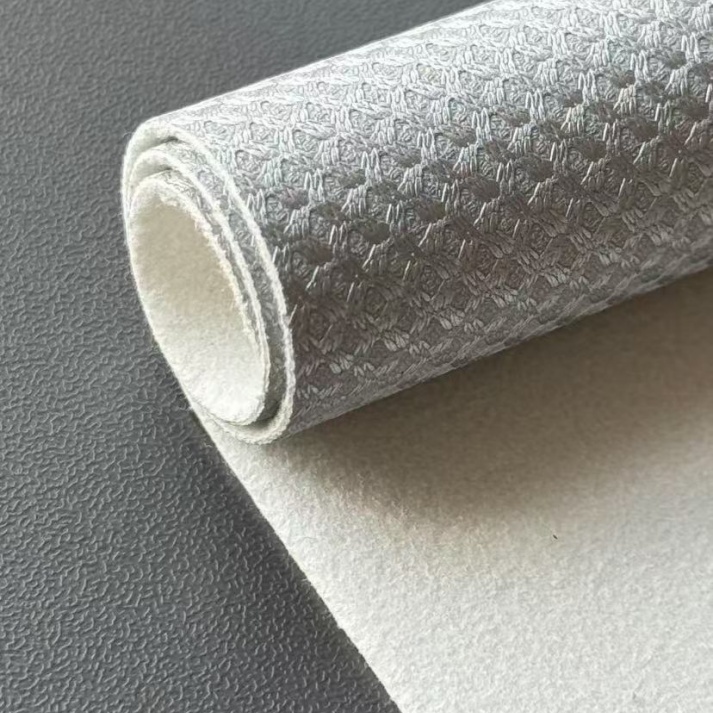

Coating and Solidification: The slurry is evenly coated on the substrate, followed by solidification in a water bath (solvent and water exchange), allowing the PU resin to form a thin film with a microporous structure.

Post-Processing: After washing and drying, embossing (creating leather texture), printing, and surface coating (to enhance hand feel and wear resistance) are performed, and the finished product is finally rolled.

Source Summary: Non-renewable petroleum resources are the ultimate raw material for PU leather.

2.2 Diverse Sources of Vegan Leather: Beyond Petroleum

Since vegan leather is a broad category, its manufacturing process and source depend on the specific material.

Petroleum-based vegan leather: This includes PU leather and PVC leather. As mentioned above, their manufacturing processes originate from the petrochemical industry.

Bio-based vegan leather: This is at the forefront of innovation and is sourced from renewable biomass.

Fruit-based: Pineapple leather (Piñatex) utilizes cellulose fibers from pineapple leaves; apple leather utilizes peel and pulp fibers from the pomace left over from the juice industry.

Mushroom-based: MuSkin (Mylo) utilizes mycelium (the root-like structure of mushrooms) grown in a laboratory to create a leather-like network. Plant-based: Cork leather comes from the bark of the cork oak tree, which is then recycled. Tea-based leather and algae-based leather are also under development.

Recycled materials: For example, polyester-based PU leather made from recycled plastic bottles gives waste new life.

The process for these bio-based materials typically involves: biomass collection -> fiber extraction or cultivation -> processing -> combination with bio-based polyurethane or other adhesives -> finishing.

Source Summary: Vegan leather can be derived from non-renewable petroleum, renewable biomass, or recycled waste.

Chapter 3: Comparison of Characteristics and Performance - A Pragmatic Perspective

3.1 Physical Properties and Durability

PU Leather:

Advantages: Lightweight, soft texture, a wide variety of patterns and colors (can mimic any texture), high consistency (no natural blemishes), waterproof and easy to clean.

Disadvantages: Durability is its biggest drawback. After long-term use, the PU coating on the surface is prone to wear, cracking, and flaking, especially in areas that are frequently bent. Its lifespan is generally much shorter than that of high-quality genuine leather. Its breathability is average. Other Vegan Leathers:

Petroleum-based (PVC/Microfiber Leather): PVC is durable but stiff and brittle; Microfiber Leather offers exceptional performance, with durability and breathability approaching that of genuine leather, making it a high-end synthetic leather.

Bio-based: Performance varies, presenting both a key focus and a challenge in current R&D.

Common Advantages: They often possess a unique natural texture and appearance, with subtle variations from batch to batch, further enhancing their uniqueness. Many materials possess a degree of inherent breathability and biodegradability (depending on subsequent coatings).

Common Challenges: Durability, water resistance, and mechanical strength are often inferior to those of established synthetic leather. They often require the addition of PLA (polylactic acid) or bio-based PU coatings to enhance performance, which can affect their ultimate biodegradability.

3.2 Appearance and Touch

PU leather: Designed to perfectly mimic animal leather. Through advanced embossing and printing techniques, it can be indistinguishable from the real thing. However, experienced users can still distinguish between leather by its feel (sometimes plasticky and with varying temperature sensitivity) and its scent.

Bio-based vegan leather: Typically, the goal is not to perfectly imitate, but rather to highlight the unique beauty of nature. Piñatex has a unique organic texture, cork leather has a natural grain, and mushroom leather has its own characteristic wrinkles. They offer an aesthetic experience distinct from traditional leather.

Chapter 4: Environmental and Ethical Impacts – Core Areas of Controversy

This is the area where PU leather and the concept of "vegan leather" are most prone to confusion and controversy.

4.1 Animal Welfare (Ethics)

Consensus: On this dimension, PU leather and all vegan leathers are the clear winners. They completely avoid the slaughter and exploitation of animals in the leather industry and align with the ethical demands of veganism.

4.2 Environmental Impact (Sustainability) – A Full Life Cycle Assessment is Mandatory

PU Leather (Petroleum-Based):

Disadvantages: Its core raw material is non-renewable petroleum. Production is energy-intensive and may involve harmful chemical solvents (although water-based PU is becoming increasingly popular). The biggest issue is that it is non-biodegradable. After the product's lifespan, it will remain in landfills for hundreds of years and may release microplastics. Advantages: Compared to traditional leather production (which is highly polluting, water-intensive, and requires animal husbandry), its production process typically has lower carbon emissions, water usage, and land use.

Bio-based vegan leather:

Advantages: Utilizing agricultural waste (such as pineapple leaves and apple pomace) or rapidly renewable biomass (mycelium and cork) reduces dependence on petroleum and enables resource recycling. The environmental footprint of production is generally lower. Many base materials are biodegradable.

Challenges: "Biodegradability" isn't absolute. Most bio-based leathers require a bio-based polymer coating to achieve durability, which often means they can only be industrially composted rather than decompose quickly in the natural environment. Large-scale agricultural production can also involve issues with pesticides, fertilizers, and land use.

Key Insight:

"Vegan" doesn't equal "environmentally friendly." A PU bag made from petroleum, while vegan, may have a high environmental cost throughout its lifecycle. Conversely, a bag made from pineapple waste, while an environmentally friendly innovation, may not currently be as durable as a PU bag, leading to faster disposal and similar waste. The entire product life cycle must be examined: raw material acquisition, production, use, and end-of-life disposal.

Chapter 5: Cost and Market Application—Real-World Choices

5.1 Price

PU leather: One of its greatest advantages is its low price, making it a favorite for fast fashion and mass consumer goods.

Bio-based vegan leather: Currently mostly in the R&D and small-scale production stages, it is expensive due to high costs and is often found in high-end, niche designer brands, and eco-friendly brands.

5.2 Application Areas

PU leather: Its applications are extremely broad, covering nearly all sectors.

Fast fashion: Apparel, shoes, hats, and accessories.

Furniture interiors: Sofas, car seats, and bedside tables. Luggage: Affordable handbags, backpacks, and wallets.

Electronics: Phone cases and laptop covers.

Bio-based vegan leather: Its current application is relatively niche, but is expanding.

High-end fashion: Limited-edition shoes and bags created in collaboration with renowned designers.

Eco-friendly brands: Brands with sustainability as their core value.

Accessories: Watch straps, eyeglass cases, and small leather goods.

Chapter 6: Identification Methods: PU Leather:

PU leather can be identified by smelling, observing the pores, and touching it.

PU leather has no fur smell, only a plastic one. No pores or patterns are visible. If there are obvious signs of artificial carving, it is PU, feels like plastic, and has poor elasticity.

Vegan Leather: Due to its wide variety, identification methods are more complex. For traditional synthetic leather, refer to the identification methods for PU leather. For new plant-based vegan leather, you can identify it by checking the product label and understanding the production process.

Market Trends: PU Leather: With growing awareness of sustainability and animal ethics, the market demand for PU leather, as a man-made leather, may be affected. However, due to its price advantage and good durability, it will continue to occupy a certain market share.

Vegan Leather: The growing number of vegetarians has driven the popularity of synthetic leather. New plant-based vegan leather, due to its environmentally friendly and sustainable characteristics, is gaining increasing attention and favor among consumers.

Chapter 7: Future Outlook - Beyond the PU vs. Vegan Difference

The future of materials is not a binary choice. The development trend is integration and innovation:

The environmental evolution of PU leather: developing bio-based PU resins (derived from corn and castor oil), using fully recycled materials, and improving durability and recyclability.

Performance breakthroughs in bio-based materials: addressing durability and functionality shortcomings through technological means, reducing costs, and achieving large-scale commercial application.

The ultimate goal of the circular economy: developing truly fully biodegradable or highly recyclable composite materials, considering the product's "end point" from the outset of design, and achieving a cradle-to-cradle closed loop.

Conclusion

The relationship between PU leather and vegan leather is intertwined and evolving. PU leather is the cornerstone of the current vegan leather market, satisfying widespread demand for animal-free products. Emerging bio-based vegan leather represents a pioneering experiment in exploring more responsible ways to coexist harmoniously with nature, looking to the future.

As consumers, it's crucial to understand the complex meaning behind the term "vegan." It represents a commitment to freeing animals from suffering, but the environmental weight of this commitment must be measured by the specific composition, production methods, and lifecycle of the material. The most responsible choice is one that is based on sufficient information, weighing ethics, the environment, durability, and cost to find the balance that best suits your values and lifestyle.

Post time: Sep-11-2025