Short Description: Cork leather is derived from oak bark, an innovative and eco-friendly leather fabric that feels comfortable to the touch as if it were leather.

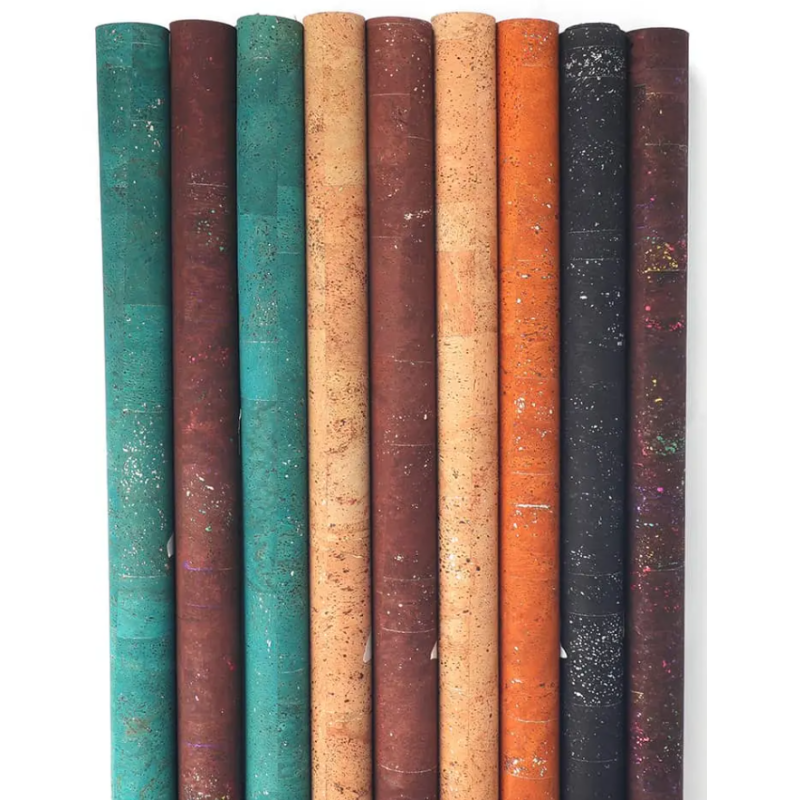

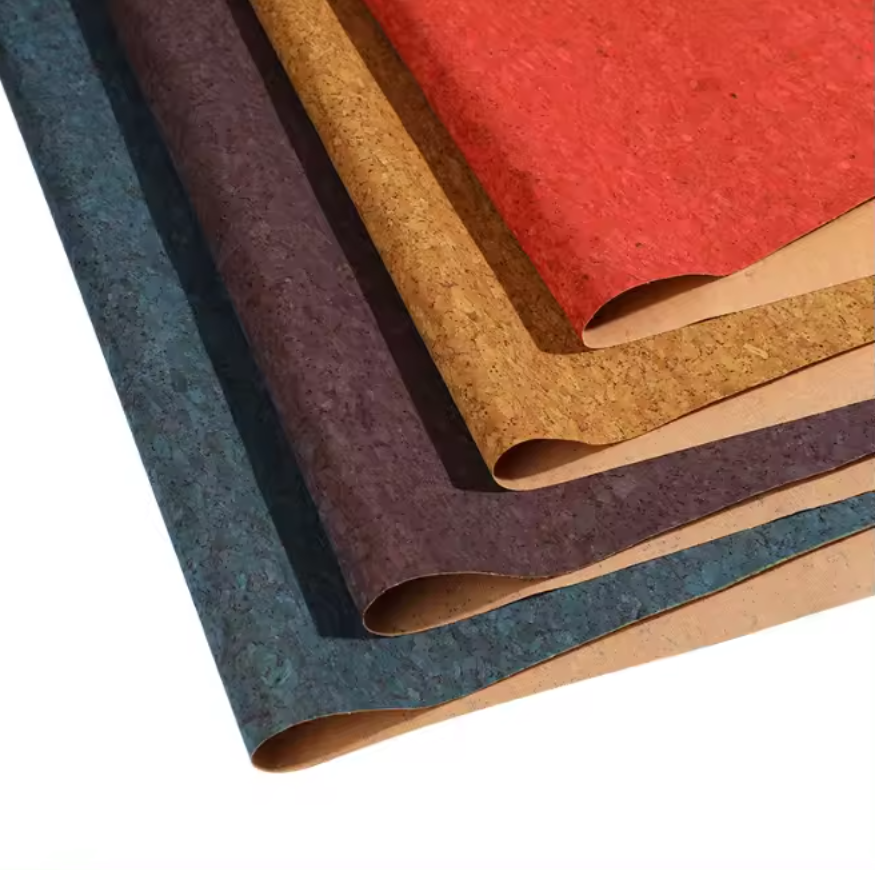

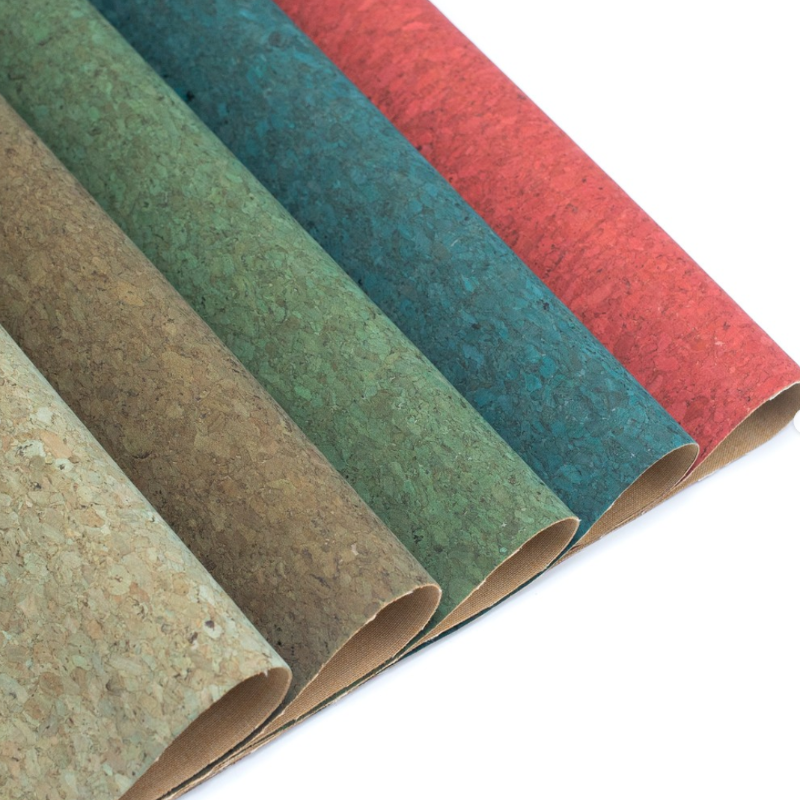

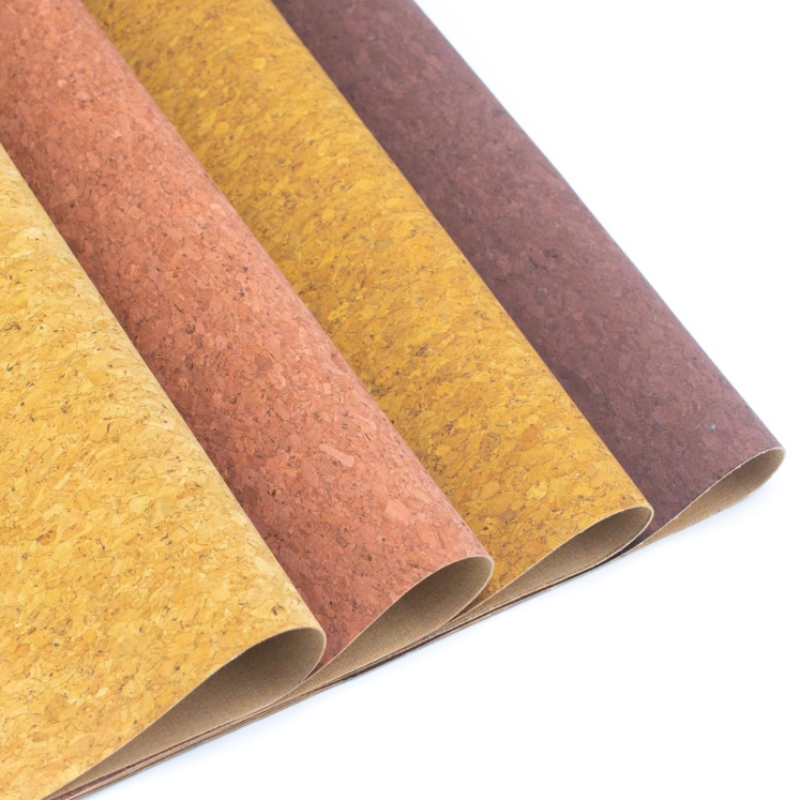

Product Name:Cork Leather/Cork Fabric/Cork Sheet

Country of Origin:China

Technical and Physical Characteristics:

- Touch pro quality and Unique outlook.

- Cruelty-free, PETA applied, 100% animal-free vegan leather.

- easy to maintain and long-lasting.

- Durable as leather, versatile as fabric.

- Waterproof and stain resistant.

- Dust, dirt, and grease repellent.

- AZO-free dye,no color fading issue

- Widely used on Handbags, upholstery, re-upholstery, shoes & sandals, pillow cases and unlimited other uses.

Material: Cork leather sheets + fabric backing Backing: PU faux leather (0.6mm) or TC fabric(0.25mm, 63% cotton 37% polyester), 100% cotton, linen, recycled TC fabric, soybean fabric, organic cotton, Tencel silk, bamboo fabric. Our manufacturing process allows us to work with different backings. Pattern: huge color selection Width:52″ Thickness:0.8-0.9mm(PU backing) or 0.5mm(TC fabric backing). wholesale cork fabric by the yard or meter, 50yards per roll. Directly from the original manufacturer based in China with competitive price,low minimum, customed colors

High-quality Cork Fabric with fabric support backing. Cork fabric is environmentally and ecologically friendly. This material is an amazing alternative to leather or vinyl because it is sustainable, washable, stain resistant, durable, antimicrobial and hypoallergenic.

Cork fabric has a similar handle to leather or vinyl. It feels like a quality leather: it’s soft, smooth, and pliable. It is not hard or brittle. Cork fabric looks stunning and unique. Use it to make handmade bags, wallets, accents on clothing, craft projects, applique, embroidery, shoes, or upholstery.

Thickness: 0.8MM( PU backing), 0.4-0.5mm(TC fabric backing)

Width: 52″

Length: 100m per roll.

Weight per Square Meter: (g/m²):300g/㎡

Composition surface layer (cork), backing (cotton/polyester/PET):Surface (cork), backing, polyester

Density: (kg/m³):Meets ASTM F1315 standard at 20°C Value:0.48g/㎝³

The density of the cork leather Tc cloth base material ranges from 0.85g/cm³ to 1.00g/cm³. This material is a high-density fiberboard made of wood fiber and glue pressed at high temperature and high pressure, with high density and good physical properties.

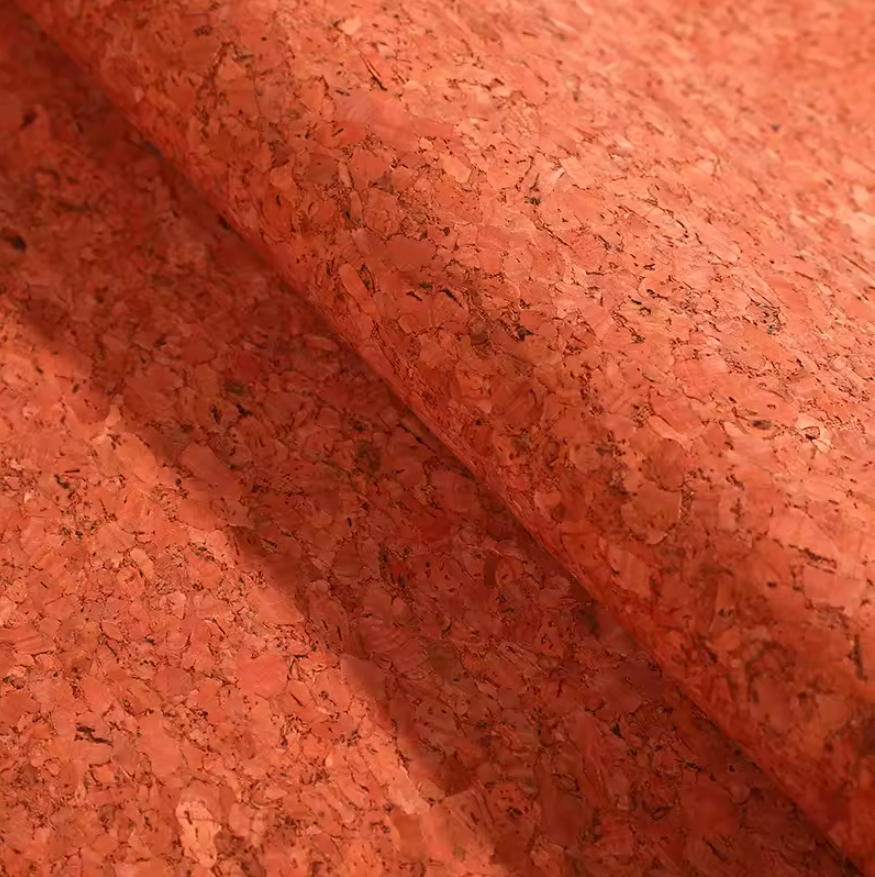

The raw material of cork leather is mainly the bark of the cork oak tree from the Mediterranean. After harvesting, the cork needs to be air-dried for six months, and then boiled and steamed to increase its elasticity. Through heat and pressure, the cork is formed into blocks and, depending on the application, can be cut into thin layers to form a leather-like material.

Cork leather has the following characteristics:

Light texture: Cork leather has a soft touch and good elasticity.

Non-heat transfer and non-conductive: Has good thermal insulation and insulation properties.

Durable, pressure-resistant, wear-resistant: Can remain stable during long-term use.

Acid-resistant, insect-resistant, water-resistant, moisture-resistant: Suitable for use in humid environments.

Sound absorption and shock absorption: It has good sound absorption and shock absorption effects, suitable for occasions where noise and vibration need to be reduced

Color: (natural or pigmented):Natural color

Surface Finish: (sheer, matte, textured):matte

Cork leather is a special fabric made of natural cork, which is often used in the fields of luggage lining, decorative materials, etc. The production process is divided into three major links: raw material processing, processing and molding, and surface treatment. Each link has strict technical standards.

The raw material processing stage is carried out in a constant temperature and humidity workshop. The purchased cork bark must meet the technical indicators of thickness 4-6 mm and moisture content 8%-12%, and there must be no wormholes or cracks on the bark surface. The operator uses a high-pressure water gun to wash and remove impurities on the surface of the bark, and the water temperature is controlled between 40℃-50℃. The cleaned bark is naturally dried on the drying rack for 72 hours, turning over every 6 hours during the period.

The processing workshop uses a CL-300 cork crusher to crush the dried bark into 0.5-1 mm particles, and the workshop temperature is maintained at 25℃±2℃ when the equipment is running. The crushed cork particles are mixed with water-based polyurethane adhesive in a ratio of 7:3, the mixer speed is controlled at 60 rpm, and the mixing time is not less than 30 minutes. The mixture is pressed into a 0.8 mm thick substrate by a double-roll calender. The calendering temperature is set to 120℃-130℃ and the line pressure is maintained at 8-10kN/cm.

The surface treatment process determines the performance of the finished product. When the substrate passes through the dipping tank, the operator must ensure that the temperature of the dipping liquid (mainly acrylic resin) is stable at 50℃±1℃, and the dipping time is accurate to 45 seconds. The drying box is divided into three temperature zones: the first section is 80℃ preheating, the second section is 110℃ shaping, and the third section is 60℃ rehumidification. The conveyor belt speed is set to 2 meters per minute. The quality inspector uses the XT-200 thickness gauge to conduct random inspections every 15 minutes, and the thickness tolerance shall not exceed ±0.05 mm.

Quality control runs through the entire production process. When raw materials enter the warehouse, the FSC forest certification documents provided by our factory must be checked, and each batch is sampled for heavy metal content. During the processing, the equipment operation screen displays the temperature and pressure parameters in real time, and automatically shuts down when the deviation from the set value exceeds 5%. Finished product inspection includes 6 indicators such as folding endurance test (100,000 bends without cracks) and flame retardancy test (vertical burning speed ≤100mm/min). Only when it meets the QB/T 2769-2018 "Cork Products" industry standard can it be put into the warehouse.

In terms of environmental protection measures, production wastewater needs to be treated in a three-stage sedimentation tank to adjust the pH value to the range of 6-9, and the suspended solids concentration should be lower than 50mg/L before discharge. The waste gas treatment system is equipped with an activated carbon adsorption device to ensure that the emission concentration of volatile organic compounds is ≤80mg/m³. The waste residue is collected and sent to the biomass power plant as fuel, and the comprehensive utilization rate is more than 98%.

The operating specifications require workers to wear dust masks and anti-cutting gloves, and infrared warning areas are set around high-temperature equipment such as calenders. New employees must complete 20 hours of safety training before taking up their posts, focusing on the "Cork Dust Explosion Prevention Operation Procedures" and "Hot Press Equipment Emergency Handling Manual". The equipment maintenance team checks the lubrication of the transmission parts every week and replaces the roller bearings of the calender every year.

Abrasion Resistance: (e.g., Martindale cycles):The number of times the cork leather TC fabric is worn in the Martindale test varies under different usage conditions, depending on a variety of factors.

In dry usage conditions, the cork leather TC fabric is worn up to 10,000 times in the Martindale test

In wet usage conditions, the cork leather TC fabric is worn up to 3,000 times in the Martindale test

Water and Moisture Resistance:Cork leather has good waterproof and moisture-proof properties. Cork leather is made from the bark extract of the Mediterranean cork oak tree (Quercus suber). After multiple processing steps, it has the characteristics of light weight, compression resistance, fireproof and heat insulation, and waterproof and moisture-proof. Its water absorption rate is less than 0.1%, and it will not deform even if soaked in water for a long time.

UV Resistance: (e.g., rating or cycles until color fading/cracking):

Cork leather has certain UV protection. Cork leather is air-dried, boiled and steamed during the production process, which makes the cork leather extra elastic and forms blocks through heating and pressure. In addition, cork leather has the advantages of soft texture, elasticity, non-heat conduction, non-conductive, non-breathable, durable, pressure-resistant, wear-resistant, acid-resistant, insect-resistant, water-resistant and moisture-resistant.

Although cork leather has certain UV protection, its specific effect may vary depending on the production process and the specific scenario of use. In order to further enhance its UV protection ability, the following measures can be taken:

Choose high-quality materials: Use cork leather materials with better UV protection.

Surface treatment: Applying an anti-UV coating such as varnish or wood wax oil on the surface of cork leather can enhance its UV protection effect.

If you have additional needs for UV protection, we will try to process and improve it for you.

Fungi and Mold Resistance: (e.g., meets ASTM G21 or similar standards):Cork leather has the following anti-fungal and anti-mold properties:

Natural anti-mold: Cork leather has been proven to not breed mold, insects, or cause human allergies.

Moisture-proof and anti-penetration: Cork resin and lignin components prevent liquids from penetrating and gases from penetrating, thereby inhibiting mold growth.

Strong stability: It has a wide temperature resistance range (-60℃±80℃), is not easy to crack and warp under humidity changes, and further reduces the environment for mold growth.

In summary, cork leather has excellent anti-fungal and anti-mold capabilities due to its material properties.

The anti-fungal and anti-mildew performance of cork leather meets the international standards ASTM D 4576-2008 and ASTM G 21.

Fire Resistance: (classification):Cork leather has flame retardant properties. The flame retardant standard for cork leather is B2. Cork leather is made from the bark of the cork tree, which contains natural fire-retardant substances, making cork leather naturally flame retardant. When encountering high temperatures, the pores inside the cork tissue can isolate the air from the flame, thereby reducing the possibility of combustion. In addition, cork leather undergoes special flame retardant treatment during processing, and flame retardants are added to form a protective layer to further enhance its flame retardant properties. The flame retardant level of cork leather can be raised to B1.

Cork leather shows lower heat release and smoke concentration when burning, because some of the substances contained in it are not easy to release a lot of energy when burning, thereby reducing the generation of smoke and toxic gases at the fire scene. This characteristic makes cork leather perform well in fire, not easy to burn and does not release toxic gases.

Therefore, cork leather not only has natural flame retardant properties, but also further enhances its flame retardant properties through processing, making it perform well in various application scenarios.

Temperature Resistance Range:The temperature resistance range of cork leather is -30℃ to 120℃. Within this temperature range, cork leather can maintain stable performance without deformation or damage.

In addition, cork leather has other excellent physical and chemical properties. For example, it has high UV resistance, can perform well in QUV tests, and can maintain good color difference performance even under extreme conditions. In terms of flame retardant safety, cork leather can pass the highest level of flame retardant test of BS5852/GB8624 and can self-extinguish within 12 seconds after contact with open flame. These characteristics make cork leather perform well in commercial spaces and high-end residences, and can meet the use needs in various extreme environments.

Flexibility / Stretch:Tensile strength complies with ASTM F152(B)GB/T 20671.7 Value: 1.5Mpa

Elongation complies with ASTM F152(B)GB/T 20671.7 Value: 13%

Thermal conductivity complies with ASTM C177 Value: 0.07W(M·K)

Cork is composed of many flat cells arranged radially. The cell cavity often contains resin and tannin compounds, and the cells are full of air. Therefore, cork is often light and soft, elastic, impermeable, not easily affected by chemicals, and is a poor conductor of electricity, heat and sound. It is composed of dead cells in the form of 14-sided bodies, which are arranged radially in hexagonal prisms. The typical cell diameter is 30 microns and the cell thickness is 1 to 2 microns. There are ducts between cells. The interval between two adjacent cells is composed of 5 layers, two of which are fibrous, followed by two cork layers, and a wood layer in the middle. There are more than 50 million cells in every cubic centimeter. This structure makes the cork skin have very good elasticity, sealing, heat insulation, sound insulation, electrical insulation and friction resistance. In addition, it is non-toxic, odorless, light in weight, soft to the touch, and not easy to catch fire. So far, no man-made products can match it. In terms of chemical properties, the ester mixture formed by several hydroxy fatty acids and phenolic acids is the characteristic component of cork, collectively known as cork resin.

This type of substance is resistant to decay and chemical erosion, so it has no chemical effect on water, grease, gasoline, organic acids, salts, esters, etc., except for concentrated nitric acid, concentrated sulfuric acid, chlorine, iodine, etc. It has a wide range of uses, such as making bottle stoppers, insulation layers for refrigeration equipment, life buoys, sound insulation boards, etc.

Adhesion of Cork to Backing:The adhesion performance of cork and cloth depends on the choice of adhesive, construction process and actual application scenario

1. Adhesive selection and adhesion performance

Hot melt adhesive: Suitable for bonding cork and cloth, with the characteristics of fast curing and high bonding strength, especially suitable for scenes that require immediate fixation. Hot melt adhesive has good adhesion to both wood and textiles, but attention should be paid to temperature control to avoid fabric burns.

White latex: Environmentally friendly and easy to operate, suitable for home DIY projects. After drying, the adhesion is firm, but a long pressing and curing time is required (recommended more than 24 hours).

Pressure-sensitive adhesive (such as special glue used for cork tape): Suitable for industrial scenes, strong adhesion and convenient operation, can be directly wrapped and pasted, and has excellent anti-slip effect.

2. Adhesion test indicators

Peel strength: The combination of cork and cloth needs to withstand separation force. If high-viscosity adhesive (such as hot melt adhesive or pressure-sensitive adhesive) is used, the peel strength is usually high.

Shear strength: If the bonding part is subjected to lateral force (such as the sole and cork pad), the shear strength needs to be tested. The porous structure of cork may affect the penetration of glue, so glue with good permeability needs to be selected.

Durability: The elasticity of cork may cause fatigue of the glue layer under long-term dynamic load. It is recommended to increase the curing time or use enhanced glue to improve durability.

3. Construction precautions

Surface treatment: The cork surface needs to be clean and dust-free (can be wiped with a damp cloth), and the cloth bottom should be dry and flat to improve the glue infiltration effect.

Compression and curing: After bonding, pressure (such as heavy objects or clamps) needs to be applied for at least 30 minutes, and ensure full curing (more than 24 hours).

Environmental adaptability: Cork is easily affected by humidity, and the cloth bottom may fall off due to washing. It is recommended to choose waterproof glue (such as polyurethane glue) for humid environments.

4. Practical application suggestions Home decoration: White latex or hot melt glue is recommended to balance environmental protection and strength.

Industrial use (such as anti-slip mats, guide roller coating): Pressure-sensitive adhesive cork tape is preferred, which is efficient and low-cost. High-load scenario: Tensile/shear strength needs to be tested, and professional bonding solutions should be consulted if necessary. In summary, the adhesion between cork and fabric can be achieved through reasonable glue selection and standardized construction, which needs to be evaluated in combination with the usage scenario.

Environmental Information

Certifications: (e.g., FSC, OEKO-TEX, REACH):Please check the attachment

Type of Binder / Adhesive Used: (e.g., water-based, formaldehyde-free):

Water-based, formaldehyde-free

Recyclability / Biodegradability:Recyclability

Applications

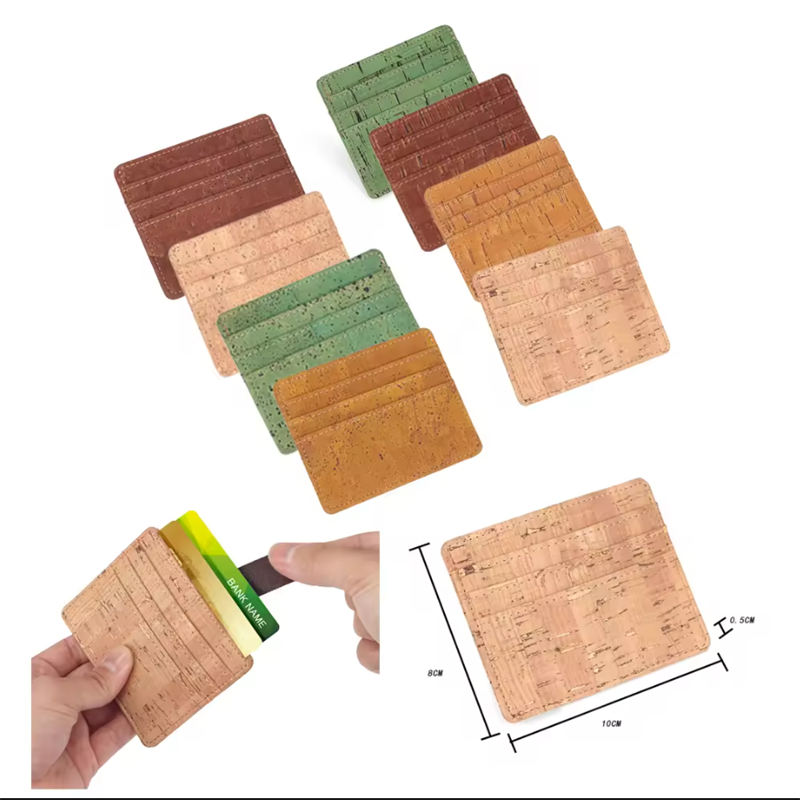

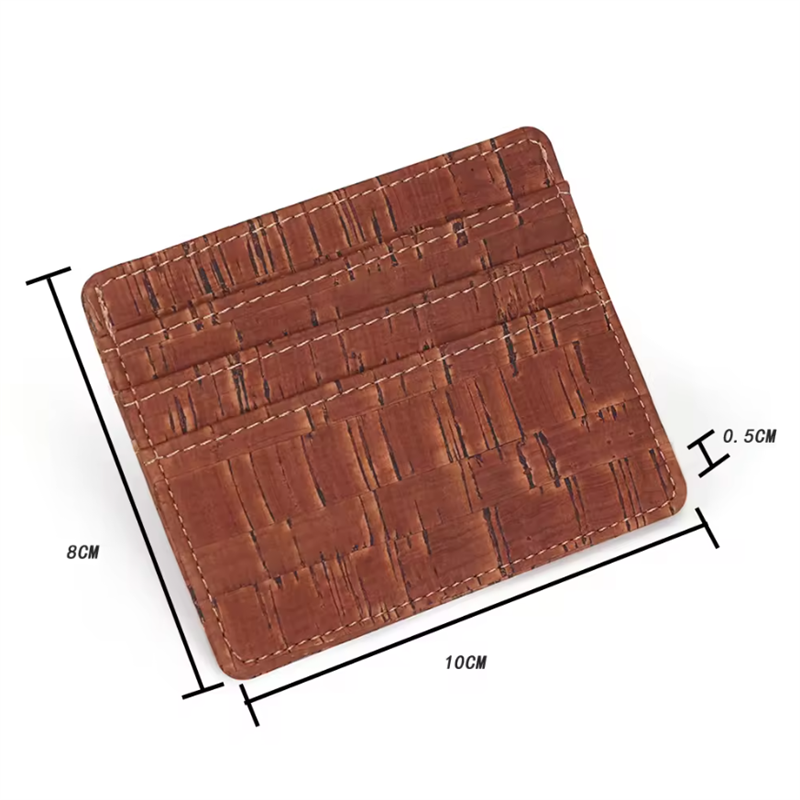

Fashion: bags, wallets, belts, shoes

Interior Design: wall panels, furniture, upholstery

Accessories: cases, covers, decorations

Other: industrial components

Handling and Care Instructions

Cleaning: (e.g., wipe with damp cloth, avoid strong detergents)

Cork leather can be cleaned by using a mild detergent and a soft cloth.

Special care is required when cleaning the surface of cork leather. Using a mild detergent is key, as strong acid or alkaline detergents may corrode the cork, causing its surface to become rough or discolored. Choosing a pH-neutral detergent can effectively avoid this problem while protecting the natural color and texture of the cork.

During the cleaning process, it is very important to use a soft cloth or sponge. Hard brushes or cloths may scratch the surface of the wood and leave marks. A soft cloth can gently wipe away surface dirt without causing damage to the wood. At the same time, cleaning should be done along the texture of the cork leather surface, which can more effectively remove dirt while reducing damage to the pattern on the surface of the cork leather.

After cleaning, it is also an essential step to dry the surface of the cork leather with a clean soft cloth in time. Ensuring that the surface of the cork leather is completely dry can extend its life and maintain its beauty.

In general, cleaning cork leather is not complicated, but it is necessary to pay attention to choosing the right detergent and tools, as well as the correct cleaning method. You can keep your cork clean and beautiful by using a mild detergent, a soft cloth, and cleaning along the grain of the wood, making sure the cork leather surface is dry after cleaning.

Recommended Cleaning Agents: (e.g., pH-neutral soap solution, mild detergent, avoid solvents):Choose a mild, non-abrasive cleaner. Avoid cleaners that contain bleach or other harsh chemicals, as these may damage cork leather. Plant-based cleaners are generally gentler and will not damage cork leather.

Storage Conditions: (e.g., dry area, avoid direct sunlight):The storage environment requirements for cork leather mainly include the following aspects:

Dry and ventilated : Cork leather should be stored in a dry and ventilated environment, avoiding damp and humid environments.

Store away from light : Cork leather should avoid direct sunlight. The ideal storage environment is ventilated but away from light to maintain its original color and texture.

Fire safety : Keep away from fire sources during storage, and ensure that the storage area is equipped with effective fire prevention equipment and fire safety measures.

Avoid contact with chemicals : During storage or use, cork leather should be avoided from contact with chemicals, especially corrosive substances such as strong acids and alkalis, to avoid damage to it.

Regular inspection and maintenance : Regularly check the storage environment of cork fabrics to ensure that they are in ideal condition and deal with any factors that may cause damage in a timely manner. In addition, handle and transport with care to avoid strong impact and squeezing to maintain its integrity

Processing Methods: (e.g., cutting, gluing, sewing)

Splicing

Cutting

Gluing

Sewing

Logistics and Durability

Logistics and transportation:

Waterproof and moisture-proof: plastic film

Edge and corner protection: pearl cotton or bubble film

Stable packaging: waterproof and scratch-resistant woven bag

Avoid stacking and avoid placing heavy objects on top of materials: When transporting, they should be stacked separately or placed with light goods to prevent squeezing and deformation, and placed on top

Packaging: (e.g., rolls, sheets):Rolls

Transport and Storage Conditions: (e.g., max humidity, temperature)Cork fabrics should be stored with the following conditions in mind:

Temperature and humidity control: Under ideal conditions, the storage environment should be kept between 5 and 30°C and the humidity should be less than 80%.

Avoid light: Avoid prolonged strong light exposure

Moisture and waterproof: The storage environment should be kept dry, and the fabric should be prevented from being soaked by rain and snow. Ensure that the packaging is good to avoid moisture penetration.

Ventilation: The storage environment should be well ventilated to promote air circulation and reduce the possibility of moisture.

Avoid chemicals: Cork fabrics should not be stored with harmful substances such as solvents, greases, acids, alkalis, etc. to prevent chemical reactions from causing damage or deterioration of the fabric.

Pest and rodent prevention: Take measures to prevent pests and rodents, as they can cause structural damage to the fabric.

Regular inspection: Whether in storage or during transportation, the fabric status should be checked regularly to detect and deal with any potential damage problems in a timely manner.

Shelf Life: (e.g., 24 months under recommended storage conditions):

Cork leather can last for decades or even longer.

Cork leather has a long lifespan and can last for decades or even longer. The specific shelf life depends on many factors, including the quality of the cork, the treatment method and the storage environment.

The quality of cork leather is the primary factor that determines its shelf life. High-quality cork leather contains more natural fibers and moisture, which help maintain the flexibility and durability of cork. After proper treatment and drying, this high-quality cork leather can maintain its physical properties for a long time and is not easily affected by rotting, deformation or cracking.

The storage environment is also important. Cork leather should be stored in a dry, ventilated and dark environment. Humid or humid environments may cause cork leather to rot or mold, while excessive exposure to sunlight may cause its color to fade or change in texture. Proper temperature and humidity control can help extend the life of cork leather.

In addition, the treatment method also affects the shelf life of cork leather. Taking appropriate measures during processing and production, such as using preservatives to enhance its ability to resist decay, and applying appropriate surface treatments to increase its durability and aesthetics, can improve the preservation of cork leather.

Overall, cork leather is a fairly durable natural material that can be preserved for a long time as long as it is properly stored and protected from adverse environmental factors. Whether it is used to make furniture, flooring, upholstery, interior decoration or other products, cork leather is a durable choice.

Expected Durability in Use: (e.g., minimum 3 years in standard use conditions):Cork fabrics can usually last more than 30 years, or even more than 50 years, under standard conditions of use. Cork fabrics have excellent anti-corrosion and durability, which makes them perform well in a variety of applications.

The main reasons why cork fabrics have a long service life include the following:

Anti-corrosion performance: Cork does not contain wood fibers, which makes it less susceptible to rot and insects. Cork products such as cork flooring, cork wall panels and cork stoppers usually need to be aged in the open air for a year before use to ensure product stability and quality.

Durability: Cork fabrics perform well under standard conditions of use, especially in outdoor environments. For example, wine corks can remain unchanged after contact with wine for hundreds of years, which shows its excellent durability.

Daily maintenance: Proper daily maintenance can extend the service life of cork fabrics. If properly maintained, the service life of cork floors can be extended to more than 50 years.

Therefore, the service life of cork fabrics under standard conditions of use is usually more than 30 years, and can even reach more than 50 years. The specific lifespan will also be affected by the use environment and daily maintenance.

Warranty of Use: (e.g., 1 year warranty covering material defects under proper use)

Under the condition of correct use, cork leather has product quality problems and can enjoy 1 year after-sales guarantee

Post time: Jun-12-2025