Comparing the Performance of Automotive Interior Silicone Leather and Traditional Artificial Leather

I. Excellent Environmental Performance

Traditional PU and PVC materials present certain environmental issues during production and use. PVC is processed with various chemicals, including plasticizers. Some plasticizers, such as phthalates, can volatilize in the high temperatures of a vehicle's interior, negatively impacting air quality and endangering the health of drivers and passengers. Due to its complex chemical structure, PU materials are difficult to degrade after disposal, resulting in a long-term environmental burden.

Silicone materials, on the other hand, exhibit excellent environmental performance. Their raw materials are extracted from naturally occurring silicon ore, and the production process is solvent-free, ensuring extremely low VOCs from the source. This not only meets current consumer demand for green and environmentally friendly travel but also reduces pollution emissions during vehicle production. After a vehicle is scrapped, silicone materials are relatively easy to degrade, reducing environmental impact and contributing to sustainable development.

II. Excellent Durability and Stability

Automotive interiors are constantly subjected to complex environments such as high temperatures, UV rays, and humidity, placing extremely high demands on the material's durability. Traditional PU and PVC materials are susceptible to aging, hardening, and cracking under these environmental influences.

Silicone materials, on the other hand, offer excellent weather resistance and chemical stability. Silicone materials used in seats and interior trims maintain excellent physical properties even after prolonged exposure to high temperatures. Silicone's chemical structure provides UV and oxidation resistance, effectively resisting environmental damage, significantly extending the lifespan of the interior and reducing maintenance costs during vehicle use.

High Safety

In the event of a collision or other vehicle accident, the safety of interior materials is crucial. Traditional PU and PVC materials can release large amounts of toxic gases when burned. For example, the combustion of PVC produces harmful gases such as hydrogen chloride, posing a serious threat to the safety of vehicle occupants.

Silicone materials have excellent flame retardant properties, effectively slowing the spread of fire and producing less smoke and toxic gases when burned.

Third, Superior Tactility and Comfort

Driving comfort is a key indicator of automotive quality, and the tactile feel of interior materials directly impacts this comfort. Traditional PU and PVC materials often have a harsh feel, lacking softness and refinement, making them less likely to offer a premium and comfortable experience.

Silicone materials offer a uniquely soft and smooth tactile feel, creating a more comfortable and luxurious atmosphere within the vehicle. Silicone leather, used in some interior designs, offers a delicate texture that feels like natural leather, enhancing the overall quality of the vehicle interior. Furthermore, the excellent breathability of silicone materials helps improve driving comfort and reduce the feeling of stuffiness caused by long rides.

IV. Safety Performance

1. Flame Retardancy

-Silicone leather has a Limiting Oxygen Index (LOI) of 32%, self-extinguishes within 1.2 seconds upon exposure to fire, has a smoke density of 12, and reduces toxic gas emissions by 76%. Traditional genuine leather releases hydrogen cyanide when burned, while PVC releases hydrogen chloride.

2. Biosafety

-It has achieved ISO 18184 antiviral certification, with a 99.9% inactivation rate against H1N1 and extremely low cytotoxicity, making it suitable for medical cabins and children's products.

V. Comfort and aesthetics

1. Touch and breathability

-Silicone feels soft and close to genuine leather, and has better breathability than PVC; traditional PU is soft but tends to harden after long-term use.

2. Design flexibility*

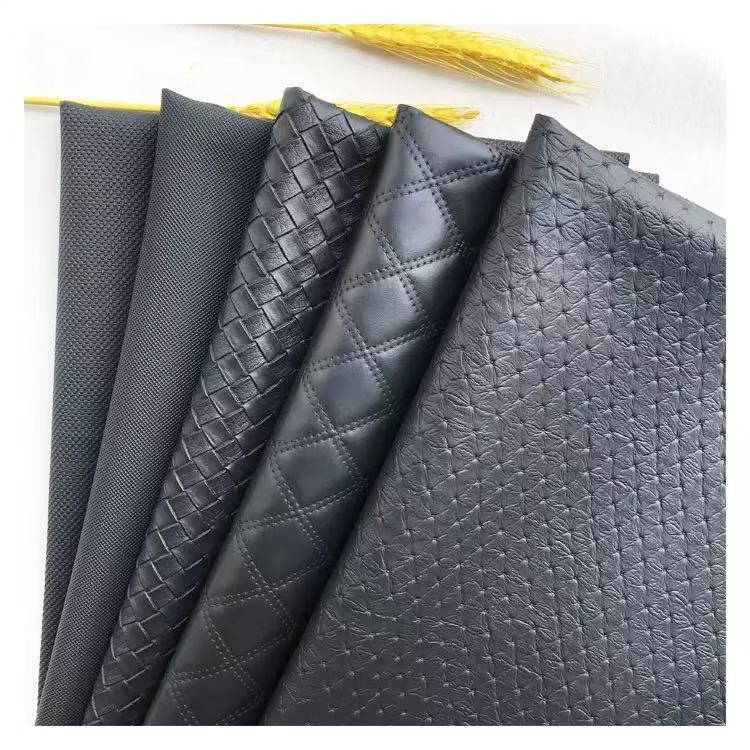

- Complex textures such as ink paintings can be embossed, but color selection is limited (because inert materials are difficult to color); traditional leather is rich in color but easy to fade.

Post time: Jul-29-2025